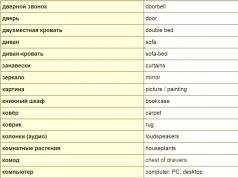

Or other liquid. Wetting is of two types:

- Immersion(the entire surface of a solid body is in contact with a liquid)

- contact(consists of three phases - solid, liquid, gaseous)

If a liquid is in contact with a solid, then there are two possibilities:

- Liquid molecules are attracted to each other more strongly than to solid molecules. As a result of the attractive force between the molecules of the liquid, it is collected into a droplet. This is how it behaves on glass, water on paraffin or a “greasy” surface. In this case, the liquid is said to does not wet surface;

- The molecules of a liquid are attracted to each other more weakly than to the molecules of a solid. As a result, the liquid tends to cling to the surface, spreads over it. This is how mercury behaves on a zinc plate, water on clean glass or wood. In this case, the liquid is said to wets surface.

AN EXPERIENCE!

If you lower the glassstick into mercury and then remove it, then mercury will not be on it. If this stick is lowered into water, then after pulling out, a drop of water will remain at its end. This experiment shows that the moleculesmercury are attracted to each other more strongly than to stack moleculesla, and water molecules attractare weaker to each other than to glass molecules.

If the molecules of a liquidare drawn to each other weaker, than to the molecules of a solid, the liquid is called wetting this substance. For example, water wets clean glass and does not wet paraffin. If the molecules of a liquid are attracted to each other more strongly than to the molecules of a solid, then the liquid is called non-wetting this substance. Mercury does not wet glass, but it does wet pure copper and zinc.

Let us place a horizontally flat plate of some solid substance and drop the test liquid onto it. Then the drop will be positioned either as shown in fig. 5(a) or as shown in fig. 5( b).

Fig.5 (a) Fig.5(b)

In the first case, the liquid chivaet solid, and in the second - no. Marked in Fig.5 the angle θ is called the contact angle. The contact angle is formed a flat surface of a rigid body and a plane tangent to the free surface of a liquid where a solid body, liquid and gas border; inside edgethe left corner is always liquid. For wetting liquids the contact angle is acute, and for non-wetting ones it is obtuse. To prevent the effect of gravity from distorting the contact angle, the drop should be taken as small as possible.

The manifestation of surface tension can be detected by observing the phenomena occurring at the interface between a solid body and a liquid.

If, when a liquid contacts a solid, the interaction between their molecules is stronger than the interaction between the molecules in the liquid itself, then the liquid tends to increase the contact surface and spreads over the solid. In this case, the liquid is said to wets solid (water on glass, mercury on iron). If the interaction between the molecules of a solid and the molecules of a liquid is weaker than between the molecules of the liquid itself, then the liquid will tend to reduce the surface of contact with the solid. In this case, the liquid is said to does not wet solid body (water on paraffin, mercury on glass).

Consider a drop of liquid on the surface of a solid body. The shape of a drop is set under the influence of three media: liquid AND, rigid body T, air or gas G. These three media have a common boundary - a circle that bounds the drop. Three forces of surface tension are applied to the line of contact of three media, which are directed tangentially into the contact surface of the corresponding two media. Let's show their direction at the point O- the point of intersection of the line of contact of three media with the plane of the drawing (Fig. 12.4.1 and 12.4.2).

These forces, per unit length of the line of contact, are equal to the corresponding surface tensions. The angle between the tangents to the surface of a liquid and a solid is called contact angle . The condition for the equilibrium of a drop (Fig. 12.4.1) is the equality to zero of the projections of the surface tension forces on the direction of the tangent to the surface of the solid body:

From this equality it follows that the contact angle can be acute or obtuse depending on the values of and . If , then the angle is acute, i.e. liquid wets a solid surface. If , then the angle is also obtuse, i.e. the liquid does not wet the solid surface.

The contact angle must satisfy the condition

If this condition is not met, then a drop of liquid under no circumstances can be in equilibrium. If , then the liquid spreads over the surface of the solid body, covering it with a thin film (kerosene on the glass surface), - complete wetting takes place. If , then the liquid contracts into a spherical drop (dew on the surface of a tree leaf).

12.5. Capillary phenomena

The surface of the wetting liquid, located in a narrow tube (capillary), takes a concave shape, and not wetting - convex. Such curved liquid surfaces are called menisci . Let a capillary in the form of a cylindrical tube with a channel radius r immersed at one end in a liquid wetting its walls (Fig. 12.5.1). The meniscus in it will have a spherical shape ( R is the radius of the sphere). Under the meniscus, the pressure of the liquid will be less than in a wide vessel, where the surface of the liquid is practically flat. Therefore, in the capillary, the liquid rises to a height h, at which the weight of the liquid column in it will balance the negative additional pressure:

where is the density of the liquid. Considering that , we get

Thus, the height of the rise of the wetting liquid in the capillary is the greater, the smaller its radius. The same formula also makes it possible to determine the depth of subsidence in the capillary of a non-wetting liquid.

Example 12.5.1. A glass tube with an internal channel diameter equal to 1mm. Find the mass of water in the tube.

Solution:

Wetting or non-wetting of the surface of a solid by a liquid also refers to surface phenomena. When a drop of liquid is applied to a solid surface, attractive forces arise between the molecules of the liquid and the solid. If these attractive forces are greater than the forces of attraction between liquid molecules, then the liquid drop will spread over the surface, i.e. liquid wets a solid. If the attractive force between the molecules of a liquid is greater than between the molecules of a liquid and a solid, then the liquid does not wet the surface.

The shape of the drop depends on the degree of wetting (non-wetting). The angle that a liquid drop forms with a surface is called contact angle. Depending on the values of the contact angle, there are three main types of wetting.

1. Non-wetting (poor wetting) - the contact angle is obtuse, for example, water on Teflon.

2. Wetting (limited wetting) - the contact angle is sharp, for example, water on a metal coated with an oxide film.

3. Complete wetting. The contact angle is not set, the drop spreads into a thin film, for example, mercury on the surface of lead, cleaned of the oxide film.

A surface that is wetted by water is called hydrophilic.

Substances with a hydrophilic surface include diamond, quartz, glass, cellulose, and metals. Surfaces wetted by non-polar liquids are hydrophobic, or olephilic. These include the surface of graphite, talc, sulfur, paraffin, Teflon.

Surfaces can be artificially given the property to be wetted by any liquid. For example, to improve the wetting of a greasy surface with water, a surfactant is added to the water. And to give water-repellent properties, they are lubricated with oil. For example, if the surface of the table is smeared with a layer of vegetable oil, then the dough will not stick to the table. This is what professional confectioners and bakers use.

Wetting plays an important role in the enrichment of ores by the method phtotations. The essence of this process lies in the fact that finely crushed ore containing waste rock is moistened with water and a surfactant is added. Air is blown through the obtained suspension. The resulting foam carries upwards particles of a valuable mineral that are not wetted by water, and the waste rock (sand) wetted by water settles to the bottom under the action of gravity.

Photation is also used in the food industry, for example, in the starch industry. The main raw material for the production of starch is corn grain, which contains, in addition to starch, protein and fat. When air bubbles are passed through the suspension, protein particles stick to them and float, forming an easily removable foam on the surface, and starch grains settle to the bottom.

Wetting is of great importance during the mechanical processing of materials - cutting, drilling and grinding. Solid bodies are riddled with cracks of various thicknesses. Under the influence of external loads, these cracks expand and the body collapses. When the load is removed, cracks can “slam”. When a solid body is mechanically treated in a liquid that wets it, the liquid, getting into microcracks, prevents them from closing. Therefore, the destruction of solids in a liquid

Goes easier than in the air.

Wetting is a surface phenomenon consisting in the interaction of a liquid with a solid or other surface.

Wetting is of two types:

Immersion (the entire surface of a solid body is in contact with a liquid)

Contact (consists of 3 phases - solid, liquid, gaseous)

The degree of wetting is characterized by the wetting angle. The wetting angle (or wetting contact angle) is the angle formed by the tangent planes to the interfacial surfaces that limit the wetting liquid, and the vertex of the angle lies on the dividing line of the three phases. It is measured by the sessile drop method. In the case of powders, reliable methods giving a high degree of reproducibility have not yet been developed (2008). A weight method for determining the degree of wetting has been proposed, but it has not yet been standardized.

Measuring the degree of wetting is very important in many industries

(paint and varnish, pharmaceutical, cosmetic, etc.). For example, special coatings are applied to the windshields of cars, which must be resistant to various types of pollution. The composition and physical properties of glass and contact lens coatings can be optimized by measuring the contact angle.

When a liquid comes into contact with the surface of a solid, two cases are possible: the liquid wets the solid and does not wet it. If, for example, drops of mercury are placed on the surface of pure iron and on pure glass, then on the surface of iron they will spread, and on the surface of glass they will have a shape close to spherical.

If the forces of interaction between the molecules of a solid and the molecules of a liquid are greater than the forces of interaction between the molecules of a liquid, then the liquid wets the solid (mercury-iron). In another case, the liquid does not wet the solid (mercury-iron).

The curved surface of a liquid in narrow cylindrical tubes or near the walls of a vessel is called meniscus. The surface of the wetting liquid near the solid rises, and the meniscus is concave (Fig. 49.1, a). In a non-wetting liquid, its surface near the solid drops somewhat, and the meniscus is convex (Fig. 49.1, b).

Figure 49.1

To determine whether a liquid is wetting or non-wetting with respect to a solid, it is possible to use the contact angle (the angle between the surface of the solid and the tangent to the surface of the liquid at point M).

For a liquid wetting the surface of a solid, the contact angle is acute (< π/2); чем лучше смачивание, тем меньше. Для полного смачивания= 0. Для несмачивающих жидкостей краевой угол изменяется в пределах π/2 << π; при полном не смачивании= π.

A wetting liquid has a concave meniscus, while a non-wetting liquid has a convex one.

Wetting depends on the ratio between the adhesion forces of liquid molecules with molecules (or atoms) of the wetted body (adhesion) and the forces of mutual adhesion of liquid molecules (cohesion).

The degree of wetting is characterized by the wetting angle. The wetting angle (or wetting contact angle) is the angle formed by the tangent planes to the interfacial surfaces that limit the wetting liquid, and the vertex of the angle lies on the dividing line of the three phases. It is measured by the sessile drop method. In the case of powders, reliable methods giving a high degree of reproducibility have not yet been developed. A weight method for determining the degree of wetting has been proposed, but it has not yet been standardized.

The measurement of wetting is very important in many industries (paints, pharmaceuticals, cosmetics, etc.). For example, special coatings are applied to the windshields of cars, which must be resistant to various types of pollution. The composition and physical properties of glass and contact lens coatings can be optimized by measuring the contact angle.

For example, a popular method of increasing oil production by pumping water into the reservoir is based on the fact that water fills the pores and squeezes out the oil. In the case of small pores and pure water, this is far from being the case, so special surfactants have to be added. The assessment of the wettability of rocks when adding solutions of different composition can be measured by various instruments.

Wettability of water.

This property is very clearly manifested in the ability of water to "stick" to many objects, that is, to wet them. When studying this phenomenon, it was found that all substances that are easily wetted by water (clay, sand, glass, paper, etc.) certainly have oxygen atoms in their composition. To explain the nature of wetting, this fact turned out to be key: energetically unbalanced molecules of the surface layer of water get the opportunity to form additional hydrogen bonds with “foreign” oxygen atoms. Due to surface tension and wetting ability, water can rise in narrow vertical channels to a height greater than that allowed by gravity, that is, water has the property of capillarity.

The wettability of a solid by a liquid is the ability of a liquid to spread over the surface of a solid under the influence of surface molecular forces.

The contour of a drop on the surface of a solid, along which three phases come into contact - solid, liquid and gaseous, is called wetting perimeter. The surfaces of pore channels of porous media are characterized by significant inhomogeneity in terms of wettability. In this regard, the wettability of the rock as a whole by various liquids can only be spoken of as an average indicator that characterizes only the ratio and geometry of areas with different degrees of wettability.

The average selective wettability of rock by formation fluids can be estimated from the rate of water absorption into the oil-saturated core. In this case, only the relative wettability of the rock is measured (relative to the wettability

bridges of another rock sample, the surface properties of which are assumed to be known). This is due to the dependence of the rate of water imbibition into a porous medium not only on the magnitude of the contact angles, but also on numerous rock properties, the effect of which is difficult to take into account.

A measure of the wetting of a solid by a liquid is the wetting angle in, formed by the surface of a solid body and the tangent to the surface of the drop at the point of its contact with the body (Fig. 7).

Rice. 7. Various cases of wetting a solid body with a liquid: liquid wets a solid body (a); intermediate state (b); liquid does not wet solid (in); 1 - liquid; 2 - air; 3 - solid

If the contact angle in< 90°, then the liquid wets the solid surface; if the angle #>90°, then the liquid does not wet the solid surface; if the angle 0 = 90°, then the fluid is in an intermediate state.

The water-wetted surface of a solid body, for which in< 90°, called hydrophilic. The surface of a solid that is not wetted by water, for which in > 90°, called hydrophobic. Wetting occurs as a result of the manifestation of molecular forces acting on the section of three phases: solid - 3, gaseous - 2, liquid - 1. The ability of a liquid to wet the rock is used to judge the magnitude of surface tension in the rock-liquid-gas or rock-liquid-liquid system.

With the balance of forces applied to a unit length of the wetting perimeter, we will have

where Gj_ 2 , Gj_ 3 and G 2 _ 3 are surface tensions at the phase boundary 1-2, 1-3, 2-3.

Rocks that can contain oil, gas, water and release them during development are called collectors. Most of the reservoir rocks are of sedimentary origin. Oil and gas are contained in terrigenous reservoirs, such as sands, sandstones, siltstones, and in carbonate reservoirs - limestones, dolomites, chalk.

Reservoir rocks must have a capacity (Fig. 8), i.e. system of pores (voids), cracks and caverns.

Rice. 8. Pore space in the rock: 1 - mineral grains; 2 - rock pore space filled with liquid or gas

But not all reservoir rocks are permeable to oil and gas; collectors. Therefore, it is important to know not only reservoir porosity, but also permeability. The permeability of rocks depends on the transverse (to the direction of movement of hydrocarbons) dimensions of voids in the rock.

It is customary to subdivide reservoirs into three types: granular, or porous (only clastic rocks), fractured (any rocks) and cavernous (only carbonate rocks).

The capacitance of the pen collector is called porosity. To characterize porosity, the porosity coefficient is used, which shows what part of the total rock volume is pores. By size, the pores are divided into supercapillary (more than 508 microns), capillary (508-0.2 microns) and subcapillary (less than 0.2 microns).

Oil, gas and water in supercapillary pores move freely under the action of gravitational forces. In capillary pores, the movement of oil, gas and water is hindered due to the manifestation of molecular cohesion forces. In subcapillary pores, the movement of oil, gas and water does not occur. In the reservoir, the movement of oil, gas and water occurs through communicating channels larger than 0.2 µm. Porosity is divided into general, open and effective.

Total porosity is the volume of all the pores in a rock. The coefficient of total porosity is represented by the ratio of the volume of all pores Vj to the volume of the rock sample V 2:

which communicate with each other. Open porosity is characterized by the coefficient of open porosity £ no as the ratio of the total volume of open pores V 0 to the volume of the rock sample V2".

There is also the concept of effective porosity, which is determined by the presence of pores in the rock, from which oil and gas can be extracted during development. Effective porosity coefficient K P ^ equal to the ratio of the pore volume U eff, through which

which the movement of oil, gas and water at certain temperature and pressure is possible, to the volume of the rock sample V 2:

the coefficient of porosity of rocks ranges from 17-25% to 40%.

An important indicator characterizing the properties of the rock to pass oil, gas and water is permeability. The unit of permeability is 1 µm 2 . This is the permeability of the rock, when filtering through a sample of which with an area of 1 m 2, a length of 1 m and a pressure drop of 0.1 MPa, the flow rate of a fluid with a viscosity of 1 MPa-s is 1 m 3 / s. Permeability depends on the size and configuration of the pores, stacking density, fracturing and the relative position of the rock particles. The permeability of fractured limestones ranges from 0.005 to 0.02 microns, and sandstones - from 0.05 to 3 microns 2 .

The porosity and permeability of oil and gas reservoirs often vary significantly within the same reservoir. The value of porosity and permeability largely affects the final oil recovery. In the process of developing oil fields, in order to increase porosity and permeability, various geological and technical measures are carried out, such as acid treatments, hydraulic fracturing, slot unloading, treatment of the formation with an oxidate, etc.

Determination of porosity and permeability of oil-bearing rocks is carried out according to the materials of geophysical studies, core samples taken during drilling, and according to the results of testing wells for inflow. In terms of permeability and porosity, according to A.A. Khanin (Table 6), there are six classes of reservoirs.

Oil and gas accumulations cannot be contained in rocks unless they are covered by impermeable rocks called seals. Clays, salts, gypsum and anhydrides can be used as tires.

Table 6

| No. p / p | The name of the breed according to the predominance of the granulometric fraction | Effective porosity, % | Gas permeability, µm 2 | Reservoir assessment by permeability and capacity | Collector class |

| Sandstone medium-grained | 16,5 | >1 | very high | I | |

| Fine-grained siltstone | >1 | very high | I | ||

| Sandstone medium-grained | 15-16,5 | >1 | high | II | |

| Fine-grained siltstone | 26,5-29 | 0,5-1 | high | II | |

| Sandstone medium-grained | 11-15 | 0,1-0,5 | average | W | |

| Fine-grained siltstone | 20,5-26,5 | 0,1-0,5 | average | III | |

| Sandstone medium-grained | 5,8-11 | 0,01-0,1 | reduced | IV | |

| Fine-grained siltstone | 12-20,5 | 0,01-0,1 | reduced | rv | |

| Sandstone medium-grained | 0,5-5,8 | 0,001-0,01 | low | V | |

| Fine-grained siltstone | 3,6-12 | 0,001-0,01 | low | V | |

| Sandstone medium-grained | 0,5 | < 0,001 | VI | ||

| Fine-grained sandstone | < 0,001 | The collector has no industrial value | VI | ||

| Coarse-grained siltstone | 3,3 | <0,001 | The collector has no industrial value | VI | |

| Fine-grained siltstone | 3,6 | < 0,001 | The collector has no industrial value | VI |

Tires are distinguished by the nature of distribution, thickness, uniformity of addition, density, permeability, and mineral composition. There are regional, sub-regional, zonal and local tires.

Table 7

Classification of tires according to E.A. Bakirov

| No. p / p | Name of tires | Subdivision sign |

| By area of distribution | ||

| Regional | Distributed within the oil and gas province or most of it | |

| Subregional | Distributed within the oil and gas region or most of it | |

| Zonal | Distributed within the zone or region of oil and gas accumulation | |

| Local | Distributed within individual localities | |

| As of oil and gas levels | ||

| Interfloor | Overlap the oil and gas level in single-story localities or separate them in multi-story localities | |

| Intrafloor | Divide productive horizons within the oil and gas level | |

| By lithological composition | ||

| Homogeneous (clay, carbonate, halogen) | Consist of rocks of the same lithological composition | |

| Heterogeneous: mixed (sandy-clay; clay-carbonate; terrigenous-halogen and others) | They consist of rocks of various lithological compositions that do not have a clearly defined layering | |

| Stratified | Consist of alternating interlayers of various lithological differences of rocks |

Regional seals have an areal distribution, are characterized by lithological consistency and significant

body thickness. They are observed within certain regions (Volga-Ural, West Siberian province, etc.)

Zonal seals are sustained within a separate zone of uplifts; in terms of distribution area, they are smaller than regional ones. Local seals are found within the accumulation site and ensure the safety of individual oil and gas deposits.

A large role in the shielding properties of tires is played by the degree of their uniformity. The presence of interlayers of sandstones and siltstones worsens the properties of tires.

Most often there are clay tires with good shielding properties, as well as rock salt, etc. The thicker the tire, the higher its insulating properties.