- Shipping cost?

Delivery is calculated based on the remoteness of your object, from the warehouse, as well as the tonnage and dimensions of the products.

- Where are you taking it from?

Delivery is carried out directly from production. Production facilities are located throughout the central region, and before entering our network, it undergoes strict quality control by the legal, accounting and quality departments.

- Where's the post office?

For the convenience of users, we have made a system for distributing the load on managers, if mail is checked by 1 person, this significantly slows down work or even leads to the fact that read letters are lost. You can leave a request through the form at the top of the site “Leave a request”, it will go to a free manager and you will be called back within 5 minutes.

- Do you have a mobile number?

For the convenience of users, we have made a system for distributing the load on managers, if a mobile phone is specified, then only 1 person can talk on it, and it will be difficult to get through to him during the season.

- Why so expensive?

The price of a product consists of several components, the main of which is the cost of the material, which determines the quality of the final product. There is also a factory mark-up and a trading company mark-up, we work on the terms of a dealer discount, therefore we do not have a mark-up separate from the factory, we earn on the fact that the factory shares with us part of its profits, and we, in turn, provide the factory with volume to ensure uninterrupted operation .

- Why can't you order less than 15 thousand? Do you only work in wholesale?

Some items are made in nearby areas and the delivery of these items adds a significant cost to the product. We have calculated that when ordering more than 15 thousand, the benefit from purchasing products from us becomes greater. If you have a small request for products that are manufactured in your area, it will be cheaper to purchase products at the nearest factories. Unfortunately, at the moment we do not have a single plant in the Moscow region that has passed our quality control.

- Where can I pick it up?

The products are manufactured at different factories, the region and the city can tell you the manager, because the factory is different for each product.

- Why such an expensive delivery?

Delivery is calculated based on the distance of the object from the warehouse of the plant. The shipping cost is divided by the number of items based on the weight of the product, ordering 1 item, the entire shipping cost will fall on it, but if there are 10 items in the order, the shipping cost will be equally distributed among these 10 items.

- Do you work with VAT?

Yes, Beton Project LLC works for OSNO and is a VAT payer. All prices on the website are inclusive of VAT.

- Why is only the office listed on the site, and not the factory?

We are a dealer of factories and carry out our activities at the office address. Because in our list there is a solid number of plants that have passed our check, it is not rational to post all the addresses of plants with products in order to complicate the search for the right plant. If you are interested in where you can take out this or that product, you can always check with the Manager or use our delivery.

- Do you have a warehouse in Moscow?

We do not have a warehouse in Moscow or the Moscow region, because this will negatively affect the value of the goods, because it will entail additional costs.

- What kind of plant? What is the name of?

Products are manufactured at different factories, you can always come to the factory and see for yourself the quality of our products. Also, if you have any doubts, you can pay for the products directly to the factory.

When arranging the slopes of roads, bridges, as well as canals for drainage, the stop block U-1 is used. Its main purpose is to limit the axial displacement of structural elements laid on an inclined plane.

The stop block U1 is made of frost-resistant concrete (F300), which has a class B25 for compressive strength and water resistance W6. At the same time, its dimensions are standard:

- length 1500 mm;

- width 400 mm;

- height 500 mm;

Slope fixing complex B8

As a rule, together with the U-1 blocks, we offer to buy the B-8 block, which is used to cover the slope surface and is made of the same concrete as the thrust piece. Concrete block B8, like the thrust block, is reinforced with steel reinforcement.

Strengthening block B8 with a size of 500x500 mm has a square shape. Grouped together, these elements form a "coverage map" of a certain part of the slope and, due to their mass, prevent erosion and soil displacement.

The favorable price of our products contributes to the fact that both the B8 blocks and the thrust element are actively sold in many regions. People wish to buy our products in large cities such as Izhevsk, Yekaterinburg, Tyumen, Moscow, Surgut, Nizhnevartovsk, Novy Urengoy.

Slope strengthening blocks P-1 and P-1M

stop blocks B 8 used in the construction of conduits for road embankments. The main purpose of such engineering structures is not only the removal of accumulated water and dirt, but also the reliable organization of the removal of sewage and atmospheric precipitation, which wash away the embankment or bridges, destroying them. Long-term operation of road structures will be impossible, therefore, permanent water collection systems with a large flow of water are built according to special rules with reinforcement. They use a complex of pick-up elements that do not allow the watercourse to collapse for a long time. To do this, in the design of the conduit, specialstop blocks B 8 . This is a rectangular monolithic element, one of the faces of which has a small bevel.

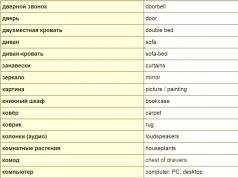

1. Options for writing markings.

stop blocks B 8 marked according to the terms of the current standard -Series 3.503.1-66 . Marking marks can be recorded in various ways:

1. B 8.

2. Block B No. 8.

2. Main scope.

stop blocks B 8 used in the construction of drainage systems for road and railway embankments, where watercourses operating under pressure are laid. Installation of blocks is carried out together with telescopic fast-flow trays. The trays are simply stacked with each other (then embedded with high strength cement mortar) on an inclined surface, forming a conduit. The stability of this design is achieved by installing support blocks on the sides. If it is necessary to widen the supporting part, blocks of other brands are used. The essence of the installation of platesB 8 - this is the creation of a reliable support that protects the watercourse from shifts and displacements that occur during the operation of embankments and bridges.

3. Marking designation.

Markings contain basic data - the type of product and its standard size, which characterizes the bearing capacity of the element. Data is formed according to the standards

Series 3.503.1-66 and applied to the side of the block with black indelible paint. Additionally, indicate the date of release of the batch of reinforced concrete products, data on the manufacturing company and weight. The designation should not be erased during the entire period of use of the block.Main dimensional characteristics

B 8 :Length = 500 ;

Width = 500 ;

Height = 80 ;

Weight = 50 ;

Volume of concrete = 0,018 ;

Geometric volume =0,02 .

4. Materials for manufacturing and their characteristics.

make stop blocks B 8 from heavy concrete of strength class B 30 and above. Products are obtained using vibrocompression technology, which is organized in the factory. Concrete must meet stringent requirements for frost resistance (grade F200-300, that is, up to 300 freeze-thaw cycles in the absence of visible damage to the product), water resistance (grade W6, high resistance to moisture absorption of concrete) and crack resistance, sinceplates B 8 operated in harsh environments of high aggressiveness. The parameters are achieved due to the introduction of special plasticizing, air-entraining and gas-forming additives into the composition. Additional hydrophobic protection increases the resistance of the product to the constant action of water.

The increase in strength characteristics is carried out by reinforcing the plates with steel spatial frames. They are made of steel class A-I, Ac-II (Heat-hardened), A-II, A-III according toGOST 5781-82 method of contact-spot welding. For the convenience of lifting massive products to a height, a metal slinging loop of the PS-1 brand is introduced into the body of the plate. Fittings are taken that are resistant to chemical corrosion, if it is planned to install stop blocks in soils of increased alkalinity. All metal parts are covered with oil paints. A set of protective measures helps to prevent the development of corrosion processes, respectively, to extend the life of the unit and the entire structure.

5. Transportation and storage.

Massive reinforced concretestop blocks B 8 transported by means of special vehicles of sufficient carrying capacity. All elements must be securely fixed against falling with steel wire. Thick boards (up to 40 mm thick) are laid between the products, which prevent product damage. Thus, the plates can be delivered in an unbeaten and suitable condition for installation.

* the actual price may differ from that indicated on the site, for clarification, download our price list.

Plate B-8- this is a small-sized reinforced concrete product in the form of a square with cut corners. As a rule, it is used in road construction to strengthen the slopes of embankments, channels, bridge cones.

Scope and method of application

Sections of roads or railways, where flooding by flood or atmospheric waters is of a regular nature, must be additionally strengthened with reinforced concrete structures. Which ones - decide the features of climatic conditions and the project. Often, a B-8 reinforcement slab is used for this purpose. Carpets made from these products are used to protect road slopes, canal beds, control structures, and bridge cones.

The absence of reinforcement with B-8 slabs in these places can lead to erosion of the embankment soil or its saturation with water. And this, in turn, can cause its collapse.

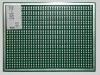

Laying of reinforcement slabs B-8

The surface corresponding to the fortification is previously divided into maps. This is convenient because if it is necessary to repair or replace a section of the carpet, there is no need to disassemble it all. B-8 slabs are laid on gravel, crushed stone preparation or geotextiles. The light weight of the product allows manual installation. Then the plates are welded together, and the sinuses formed due to the cut corners are monolithic with a solution.

The figure shows a simplified laying scheme:

Scheme of laying reinforcement slabs B-8

Production of reinforcement plates B-8

The production of reinforcement plates B-8 is carried out in accordance with Series 3.503.1-66.

materials

Since the plates will take significant dynamic loads, they must have the necessary margin of safety. Therefore, they are produced only from heavy grades of concrete not lower than M200. Water resistance and frost resistance may vary depending on the operating conditions, but W6 and F200 are usually taken. In view of the fact that B-8 reinforcement plates are often exposed to water flows with solid particles suspended in it, the surface of the product can be treated with compounds that increase wear resistance.

Dimensions

The geometric parameters of the B-8 slabs are similar to the P-1k slab. The width and length of the product is 500 mm, height - 80 mm. Regulatory documents regulate the maximum allowable deviation from the design dimensions. It is 10 mm in length and width, and 5 mm in height.

Storage and transportation

Finished B-8 reinforcement slabs are stored and transported on wooden pallets. Up to four stacks of eight plates are placed on one pallet. Mandatory constriction with safety tape. During unloading, such a structure should be picked up exclusively by the pallet itself.

How to buy B-8 plates from the manufacturer

The plant "" is located in the Tula region. But, thanks to the high quality of our products and very competitive prices, we are constantly cooperating with organizations outside of it.

Our products are regularly sent to construction sites in Moscow, Tver, Vladimir, Tambov and other regions of the Central Federal District of Russia.