The ultimate goal of the distillation process is to produce strong homemade alcohol. Unfortunately, with a simple distillation of moonshine at home, we get a product that, in addition to ethyl alcohol and water, contains a large amount of harmful substances, impurities and fusel oils. Among the distillers, it is customary to call them fractions: "heads" and "tails". The high-quality drinking part of the moonshine is called "body". Thus, correct calculation and selection of heads and tails is the key to obtaining a high-quality distillate.

The existing selection methods are based on differences in the boiling point of ethyl alcohol and harmful impurities. This gives us a real opportunity to separate the moonshine grains from the chaff. Distillation with separation of the output moonshine into fractions is called fractional distillation.

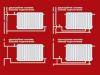

Please note that the information below assumes the use of standard moonshine stills. That is, those that consist of a distillation cube and a refrigerator. It is also relevant for models equipped with a steam generator. If the moonshine still used by you has additional structural elements and features, then look for information in the accompanying technical documentation to them or contact the manufacturers for clarifications.

Characteristics of fractions

In each case, the specific amount of fusel oils contained in moonshine and harmful substances obtained during distillation depends on a huge number of variable factors. We are talking about the ingredients used for the mash, the duration of the fermentation, the design features of the equipment and the method of distillation. In this regard, in practice, we can build exclusively on the approximate numbers and values.

Head

Many moonshiners know this faction as Pervach or Pervak. It is she who is selected first during distillation. The composition of the heads is mainly formed by acetone, methyl alcohol and acetaldehyde.

All substances included in the composition of the pervac have a lower boiling point than ethyl alcohol. That is why we can select them first. The heads are characterized by high strength and a characteristic unpleasant odor.

There is a popular belief that pervach is the best part of moonshine. Such thoughts are most likely associated with the rapid intoxication that this liquid causes. In fact, eating heads carries a serious health hazard. Severe poisoning is one of the mildest possible consequences.

In the case of the heads, our task is formulated very simply: we must collect them in a separate container and separate them from the main part of the moonshine. There are different ways to use the first on the internet, but I recommend that you just pour it out.

Body

This faction is the main one. It is the body that forms the drinking part of home brew. Its composition is based on ethyl alcohol and water, to which even with the most careful fractional distillation, a certain amount of impurities and fusel oils will be mixed. If everything is done correctly, then you should not worry about it. After all, it is these substances that form the taste and aroma (organoleptic properties) of moonshine.

These impurities will just make the difference between the technological processes of distillation and rectification. The latter is used in the production of vodka.

Tails

This fraction is usually called fusel oils or fusel oils. Its composition is extremely heterogeneous. Similar substances are similar in that their boiling point is higher than ethyl alcohol. The tails additionally stand out due to the characteristic moonshine aroma, taste and turbidity.

To prevent large quantities of fusel oils from getting into the moonshine, it is enough for us to complete the selection of the distillate body at the right time.

In the case of tails, there is no single opinion on whether to collect them or not. One thing is clear, if you do take them away, then you should not pour them out. The tails can be used to prepare the next batch of mash. To be more precise, they must be combined immediately before distillation.

Head selection

There are several basic techniques that practicing distillers use at home. For beginners, I recommend using the one that makes it clear even before the start of the distillation, their exact number or how many heads need to be selected.

1. Determined by the level of sugar content.

I think this method is the simplest and at the same time accurate. The disadvantage is that for its implementation we need additional equipment - a hydrometer-sugar meter. Many people know him as a wine meter. Naturally, the sugar content in the mash should be measured before adding the yeast. The easiest way to explain this method is with a specific example.

Suppose we have 10 liters of mash with a sugar content of 15%. We make simple calculations. 10 * 0.15 = 1.5. That is, our 10 liters of mash contains 1.5 kg of sugar. In the example, such simple numbers are specially taken. In practice, things can be a little more complicated for you.

We remember that from each kilogram of sugar we need to select 70-100 ml of heads. That is, in our example, their volume is 105-150 ml. I prefer to always act on the top bar. This does not affect the final volume of the moonshine too much, but it makes it much cleaner.

Some experienced moonshiners suggest dividing this figure in half. Take the first 75 ml of tailings at the first distillation, and the same amount at the second.

2. For ethyl alcohol.

This technique involves carrying out the first distillation without dividing the yield into fractions. After its completion, using an alcoholometer, we measure the strength of moonshine or raw alcohol. Let's also look at the situation with an example.

Suppose we have driven out 5 liters of raw alcohol with an ethyl alcohol content of 45%. We do the following calculations. 5 * 0.45 = 2.25. Thus, we have 2.25 liters of pure ethyl alcohol in the resulting distillate.

We make the second distillation fractional. We need to select 10-15% of the total alcohol volume as heads. In our case, it will be 2.25 * 0.15 = 0.3375 liters or 330 milliliters.

3. We focus on the smell.

This method is the lot of extremely experienced moonshiners who are able to distinguish heads by their characteristic odor.

In practice, for this, a clean hand is placed under the outlet stream and 2-3 drops are caught in the palm of the hand. The liquid is rubbed and sniffed. After the head odor is gone, body collection begins.

There is also a temperature method. However, in practice, it does not give unambiguous and accurate results, so I recommend that you use one of the methods described above.

Tail collection

In the case of this faction, it is extremely important not to miss the moment of the transition. In other words, we must react accurately and instantly when tails start coming out instead of the body.

These changes are monitored by measuring the strength of the moonshine in a stream. As soon as it falls below 40-41 degrees, we must react. To insure yourself against getting a large amount of fusel oils into the main container with selected moonshine, you need to replace it with a small jar closer to the end of the distillation process, in which you can take measurements.

Of course, it's best to have an alcohol meter on hand. However, if you don't have one, you can use the proven old-fashioned method. Collecting moonshine must be continued until the moment it burns. As you can see, in such a situation we only need a teaspoon and a lighter.

Let us know in the comments about your experience with head and tails selection.

Tails mean low alcohol moonshine, which is collected after lowering the fortress during distillation below 40 degrees. This fraction is saturated with "booze" and other harmful impurities, but contains ethyl alcohol, which can be distilled and get a good product. There are a number of subtleties to this approach to distillation that we would like to describe in this publication.

You can read more about the factions of the head, body and tails here -. We are extremely negative about tails, believing that moonshine should be made from quality raw materials, and not from "under-brew" with impurities... But in order to save money, many moonshiners use tailings distillation, so we decided to cover this topic and choose the optimal technology for this process.

The body output is small, but still significant.

The reason is a large amount of harmful substances, which will partially get into your moonshine even after high-quality cleaning. It seems strange to us to endanger our health in order to save a few liters of a 40-degree drink.

The quality of moonshine from " under-catch"Will be lower than from fresh mash.

If you nevertheless decide on this process, then follow the instructions described below, which will allow you to squeeze the highest quality alcohol from such raw materials.

The tails begin to drip at the moment when the fortress in the stream drops to 40 degrees.

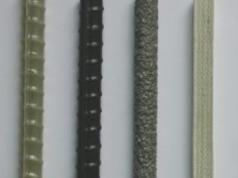

A moonshine still with a dry steam tank and a reflux condenser noticeably reduces the content of harmful substances in the moonshine.

How to properly distill the tails into moonshine?

There are several ways to do this:

Braga mixes well with tails. But it is impossible to increase the strength of the mixture above 20 degrees.

- Use a clean mix of tailings from different runs.

- Mix tails with mash.

- Mix unsuccessful or tasteless moonshine with tails.

It is important to comply with the main condition: before distillation, moonshine must be diluted with clean water to a strength of 20 degrees... It is such a liquid that lends itself well to distillation and the separation of fractions is obtained of high quality.

If you pour a distillate of 30 or 40-degree strength into a distillation cube, then the output will be low-quality moonshine.

Do I need to separate fractions during distillation?

Necessarily! This is precisely the main idea: to clear the "under-catch" from harmful impurities, dividing it again into fractions. Thus, it can be the third or even the fourth distillation of the distillate.

For 20 liters of tailings diluted to 20% ABV, you get something like the following distillation:

The ratio of fractions to each other.

- Head - 0.43 liters.

- Body - 5.11 liters.

- Tail - 0.62 liters.

Ideal conditions shown. Feel free to make an error in the region of 10% minimum.

How to mix tails with mash correctly?

To draw up the correct proportion, you will need to find out the strength of your matured mash (usually it ranges from 10 to 14 degrees), and then bring it to a 20-degree strength.

It makes no sense to make the mash stronger, as the quality of the drink will begin to deteriorate.... Therefore, it is better to take mash with poor performance, dilute it with tails and then overtake it. In this case, you will effectively manage your raw materials.

Can tails be drunk?

Definitely not.

There is a legend among moonshiners that the heads and tails of moonshine are the strongest. You don't need to drink a lot, drunkenness occurs quickly, and these fractions are in excess after distillation.

In fact, it is not drunkenness that occurs, but poisoning: fusel oils and other impurities have a very negative effect on the digestive system, as a result of which the body begins to fight the poison and the state of health worsens. These symptoms are mistaken for the cheerful effect of alcohol, but in fact, not so little ethyl alcohol is drunk, and it works differently in good drinks.

Instructions for the correct distillation of tailings

Moonshiner Guru Konstantin Kapochkin recommends doing this:

- We carry out the first distillation of moonshine without separation of fractions.

- We carry out the second fractional distillation with the three fractions described above.

- We collect tails from different routes, then dilute them to 20 degrees and send them for distillation.

- We separate fractions using the same technology as during conventional distillation.

Reflections on this topic can be viewed on the Youtube channel Moonshine Sanych. The video link is provided below:

"Tails" are added to the mash, wishing to increase the degree of the drink. Waste-free production among moonshiners is a common practice. For this reason, so often the heads and tails, rich in fusel oils, are used to make various alcoholic beverages. How effective is the method, and how not to spoil the distillate with experiments?

It is no secret that the entire distillation process can be divided into stages, or fractions. As a result, this makes it possible to improve the quality of the drink and make it drinkable.

So, why do they carry out the division into fractions:

- In order to eliminate essential oils and impurities.

- Improve the taste and aroma of the drink.

If we abandon fractional distillation, then the result is a distillate of dubious quality, with a sharp aroma and taste. Among moonshiners, it is customary to divide distillation into several stages:

- Branch of "heads". This is pervach, rich in fusel and aldehydes, it can be used for technical needs or for the purpose of creating raw alcohol.

- Getting a "body" or "heart". They start when the alcohol level drops to 40–45 degrees, such alcohol does not contain harmful substances in high concentration.

- Branch of the "tail" part. They start when the fortress decreases, carry out until the degree drops to 20-15, there are no restrictions or prohibitions on this matter.

This process is called fractional distillation; in this way, the mash is converted into an alcoholic product suitable for drinking and making noble drinks.

Each faction has its own characteristics, you need to learn how to select. And also to start and finish procedures on time, so as not to face certain problems and not spoil the taste of alcohol.

"Heads"

"Heads" of moonshine are the part that is separated from the "body", it has the following characteristics:

- Specific smell.

- Unpleasant taste, scalding the mucous membrane of the mouth.

- High fortress.

Drinking "heads" is not worth it for several reasons: they have an unpleasant aroma, taste and lead to a severe hangover due to the content of harmful impurities and substances in the composition.

Despite the fact that the strength of "pervak" can reach 60 degrees, it is dangerous to health, you can face severe signs of intoxication.

Usually "heads" are used to create raw alcohol, you can use them for technical needs. Such a product is unsuitable for the creation of noble drinks, wine or liqueurs.

"Body"

This moonshine can be drunk, it has a strength of 40-45 degrees in the stream, the selection begins after the previous part finishes the exit.

Home distillate body characteristics:

- does not smell like booze;

- has normal taste characteristics;

- used to create noble drinks;

- suitable for re-distillation.

"Body" has high characteristics, has a pleasant taste and aroma, it is actively used in home brewing, kept in an oak barrel, re-distilled, insisted on herbs and nuts.

"Tails"

"Tails" do not make moonshine more pleasant, they have the following effect on the product:

- Reduce its strength.

- Change the organoleptic characteristics.

- Make it unsuitable for making noble drinks.

This part is of low quality, is used for several purposes, and is often simply poured out by distillers, as unnecessary. However, this is not always done with the "tails", they are often "put into business", they do it in various ways.

Using "tails"

What can you do with the "tails" of moonshine? This is actually a rhetorical question, which not every distiller can answer. In practice, everything is simple, this part is used for the following:

- creating home brew and increasing its strength;

- obtaining alcoholic beverages.

If the brew is put on wild yeast, using grain or fruit as the main raw material, then the addition of "tails" will significantly increase the degree of moonshine, which will be obtained in the end.

"Tails" are added not during the creation of the mash, but before the start of distillation, so as not to spoil the smell and taste of the drink with frank booze.

If there is no desire to pour out the "tail" part, then it is saved by pouring it into a container made of dark glass. When a sufficient amount of "tails" has been collected, the product is re-distilled.

Alcohol is distilled in order to improve the quality indicator, to obtain raw materials suitable for drinking.

But do not dilute the "head" with a part of the "tail", as this is fraught with negative consequences. Yes, as a result of manipulations, the strength of pervak will decrease, but the smell, taste and quality of the drink will leave much to be desired. As a result of the use of low-quality alcohol, there is a risk of severe intoxication; drinking such a drink is dangerous to life and health.

How to separate the "tails"?

The separation of the "tail" part takes place in several stages and does not differ in complexity. The whole process goes according to the following scheme, it is not recommended to break the algorithm, as this can spoil alcohol, make it undrinkable.

So what to do:

- Start sampling "tails" when the strength in the jet falls below 40 degrees.

- Continue the process until the fortress drops to 20 degrees.

The alcohol strength level is determined using an alcohol meter, there are no strict restrictions, some distillers continue to select until the strength drops to 15–20 degrees.

If there is no alcohol meter, then it is worth resorting to using a simple test:

- soak a paper napkin with moonshine;

- try to set it on fire.

If the paper soaked in alcohol is on fire, then you can continue collecting "tails", some moonshiners finish it at the moment when outright fuzz starts to come out of the apparatus.

If we talk about the repeated distillation of "hosts", then it is carried out with separation into fractions, the "tails" are again separated, used for their intended purpose or poured out.

You should not try to make a noble drink out of this part. Waste-free production is good, but there is no point in using an outright surrogate. Fusel oils, ethers and aldehydes can spoil any product, turn grain mash into low-grade alcohol and completely ruin the taste and aroma of the drink.

This is not just data that distillers, for one reason or another, take into account. The temperature indicator helps to create a high quality alcoholic drink at home.

It is known from the course of chemistry and physics that alcohol boils at a temperature of 78 degrees, its boiling continues until the indicator reaches 83 degrees. Water boils at a temperature of 100 degrees.

Moonshine distillation temperature

Braga is a mixture of water and alcohol (and not only), it contains a sufficient amount of impurities that boil when a particular temperature is reached. So, in order to get a high quality product, it is worth having a certain idea of how the degrees affect the distillation process.

A little about the temperature regime

The answer to the question at what temperature the moonshine begins to drip is of interest to many fans of making a distillate at home. The thing is that it is difficult to answer it unequivocally. The indicator is in the range from 78 to 85 degrees.

Some moonshiners claim that moonshine boils when the temperature reaches 82-83 degrees.

At the same time, fusel oils and harmful impurities boil at a completely different temperature. In order not to get confused in the mode during distillation, it is worth equipping the distiller with a thermometer. The sensor will help you track indicators and produce high quality moonshine.

So here's the power of degrees:

- compliance with the regime helps to produce, that is, to divide the distillate into fractions (to cut off the heads and tails, thereby improving the quality of the product several times);

- avoid getting into the main fraction (the so-called body) of tails and heads, and with them harmful impurities.

Guided by time, trying to understand the degrees, distillers pursue one single goal - to improve the quality of moonshine. Influence its taste and aroma. But it is worth remembering that the indicators depend not only on the amount of ethyl alcohol in the wash, but also on the moonshine still.

It should be borne in mind that a distiller with a steam boiler has its own characteristics, in addition, in devices of various designs, the temperature regime has different fluctuations. Everything is quite subtle here, since it is worth considering not only the main design features of the apparatus, but even the metal from which the distiller was made.

Difficulties can arise if the unit was made in a handicraft way. The design does not provide for the presence of a thermometer, and there is nowhere to mount it.

Some craftsmen equip a distillation cube with a sensor, tracking temperature fluctuations with it. But such data can hardly be called accurate. However, this is better than nothing.

Having figured out why you need to monitor the indicators, it is worth moving on to the features of fractional distillation.

In moonshine, there are no unimportant stages or those where you can "cheat". Each stage requires adherence to certain technologies and rules, but this is especially true for distilling the mash into moonshine. It is not easy to get high-quality alcohol at home, but we will try to explain in detail what follows and how to properly distill the mash into moonshine.

Checking the mash before distillation

For the initial data, let's take sugar mash - in terms of popularity among moonshiners, it has no equal. The principle of working with fermented food is the same, regardless of whether you cook it with sugar, grains or fruit.

You can check the readiness of the mash in different ways, but it is advisable to practice several at once, so as for sure not to be mistaken.

- Settled Glove

Using a medical glove instead of a lid with a water seal is a favorite technique of distillers. With its help, you can easily determine the moment when fermentation stops. With active fermentation of fungi, a large amount of carbon dioxide is released, which keeps the glove in a "standing" position. Once fermentation has stopped, the glove is deflated completely.

To remove carbon dioxide, small holes must be made in one or two fingers of the glove.

- Distinct layer separation

Even sugar mash separates into sediment and lighter layers. The upper layers of the wort ready for distillation are quite light, which indicates its complete readiness for distillation.

- Burning match

The easiest way to understand whether the mass emits carbon dioxide or not is to light a match over the mash, and if it continues to burn, this is also a readiness indicator.

At the end of fermentation, the fungi process all the sugar, so the sweetness is no longer felt. But there is obvious bitterness.

- Alcohol aroma

This is not the surest sign, but in combination with others, it can also be regarded as an indicator of the end of fermentation.

Ideally, all 5 signs coincide, but in practice, a fallen glove is enough and a taste of the mash is enough so that you can already start.

Degassing - removal of carbon dioxide residues

Distillation of mash into moonshine begins with the complete removal of carbon dioxide as a product of fungal metabolism. We carefully remove it from the sediment, it is best to do this with a hose so that it does not disturb it when the bottle is overturned. Then pour it into a saucepan and put it on gas, without closing the lid, and heat it to 50 ° C.

Stir the liquid constantly while heating to remove any remaining CO2.

After 5-7 minutes of maintaining the temperature at around 50 ° C, the pan can be removed from the heat and the solution can be poured into the distillation cube.

VIDEO: Checking readiness in the old old-fashioned way

Clarification of mash with bentonite

Immediately, we note that this stage is optional, but such manipulations will additionally cleanse the mash from dissolved impurities and oils even before the distillation begins.

Bentonite is a natural material based on white clay with the ability to adsorb insoluble impurities.

Prepare a solution at the rate of 1 tbsp. for 10 liters of alcohol. First, it is grinded in a blender, and then mixed with water until it thickens like sour cream. Then pour it into the main container with the mash in a thin stream and stir it vigorously. After 24 hours, the solution can be removed from the sediment.

First distillation

We poured the mash into the alembic, collected all the elements, connected the water to the refrigerator and started heating. This is the most crucial moment, where it is very important to select in time harmful impurities and fusel oils.

First, let's define the terms:

- Head

The first fraction of the distillate, where a large amount of harmful impurities is concentrated, in particular, methyl alcohol and acetaldehyde. The first to come out are those chemical elements whose boiling point is lower than the boiling point of alcohol (77 ° C). On average, the volume of heads is 50-60 ml from each kilogram of sugar used in the preparation of mash.

The heads are cut off until the smell of acetone is felt. Taking a few drops at a time, rub them on your wrist to feel the scent more clearly.

The middle part of the distillate, for which the distillation of the mash into moonshine is started. It is collected immediately after the heads and until the fortress drops to 40 ° (the first drops of alcohol have a fortress of more than 80 °).

- Tails

The final fraction, where already heavy fusel and essential oils are concentrated. If the moonshine still has a dry steamer, there will be very few tails - most of the booze will settle in it.

Some experts recommend collecting the tails and using them in the next batch of mash. Frankly speaking, there is no point in this - this does not affect either the organoleptic properties or the taste of the finished product.

VIDEO: Sugar moonshine. Heads, body, tails - selection methods

So, the first distillation is to carefully separate the fractions and collect the body of the moonshine. But even if some mistakes were made at this stage, you can easily fix it on the second distillation of the mash.

Only the alcohol that was obtained from the distillation column or Istomin's alcoholic product with two dry-kettle does not need to be re-distilled.

Temperature control

If you properly observe the temperature regime, the output of moonshine will be maximum. For convenience, we will distribute the temperature in separate stages to make it clear.

- Immediately after placing the cube on the stove, maximize the intensity of the flame and bring it to 70 ° C for a quarter of an hour, that is, 4-5 ° C per minute.

- Then we reduce the fire to a minimum, so that now the increase occurs more smoothly (no more than 1 ° C per minute) and so we heat it up to 92-94 ° C. At this moment, the first drops begin to come out, which are captured in a separate container. These are the very heads that we wrote about earlier.

If you do a double distillation of moonshine, at the first, 30 ml are taken from each kg of sugar. On the second - the same amount.

- After all the heads have been cut off, remove the dry box, wash it and put it back in place, put another container and collect the body. You can adjust the temperature up or down so that the speed is at least 120 drops per minute. The limiting indicator is 98.5 ° C.

- At the same time, we check the temperature of the finished product. When the water is cold in the refrigerator, the alcohol comes out almost cold. If the alcohol is hot, circulate the water in the dephlegmator.

Intermediate cleaning

Since we are telling you how to distill the mash into moonshine correctly, it is necessary to remind you of the necessity of filtering the product throughout the entire cycle.

Intermediate cleaning allows you to remove a certain amount of harmful impurities. They will not all leave, but during the second run they will be separated more actively.

For cleaning, you can use the most primitive coal column. Cut off the bottom of a plastic bottle at a distance of 3 cm from the bottom of the bottle. Turn it over, insert it into another container like a funnel and stuff it with small fragments of charcoal very tightly so that there are no air gaps. Pour the alcohol on top and wait for it to seep into the bowl.

Second leg

You can re-distill the mash again according to the same rules as the first, starting from temperature and ending with cutting off the tails. The goal of re-distillation is to maximize the purification of alcohol from chemical elements. After the end of the run, the alcohol strength will be 80-85 ° and it will be crystal clear.

Purification after distillation

You can use the same good old charcoal filter or use any other options:

- potassium permanganate - 2 gr. for every liter of alcohol. Stand for 24 hours, strain;

- vegetable oil - 20 ml per kg, leave for 24 hours, after which a film is collected on top;

- freezing - express cleaning, after which the drink is ready for use in 2 hours.

Which one to choose is not important. At least everything is possible, but we repeat once again, it is impossible to rid alcohol completely of the entire volume of impurities.

Dilution with water

Naturally, 80 ° C alcohol will be overcome by very few people, and therefore dilution with water to the usual 40 ° is practiced.

After double distillation of moonshine into mash and correct dilution with water, you get a very high-quality vodka without a characteristic fusel smell, but 100% natural taste.

The amount of water is determined by the formula:

It's simple - you need 5 liters of spring or purified water to properly dilute the moonshine.

There are certain rules for breeding too:

- We dilute all the moonshine at once using the entire volume of water.

- Pour the moonshine into the water in one motion.

- We use only purified water, ideally well or spring water.

If the drink becomes cloudy during dilution, add activated charcoal or charcoal and leave for a day so that all impurities are gone.

You can clean the moonshine very quickly and do not give it time to mature. To do this, pour the already diluted product into a bottle, close it in the freezer and after 2 hours you will have a product of excellent quality.

This express method has no disadvantages. These drinks are identical in quality, taste and organoleptic properties.

VIDEO: Recipe for making mash from sugar

One of the most important main stages of home brewing is the stage of distillation of the mash. At this stage, it is important to follow all the rules in order to get pure moonshine without harmful impurities and unpleasant odors. The most important condition is to maintain the desired, optimal temperature.

Braga is a mixture of alcohol and water. Distillation occurs due to the temperature difference between water, alcohol and fusel oils. The boiling point of water is 100 ° C, and that of alcohol is about 78 ° C. Hence the conclusion that the boiling point of the mash is between 78 and 100 ° C. The higher the concentration of alcohol in the mixture, the lower the boiling point and the more likely it is to obtain a high-quality distillate.

During the selection of the main fraction, it is necessary to maintain a temperature of 78-83 ° C.

A thermometer is needed to control the temperature. It is best to use a liquid thermometer built into the evaporator.

To get high-quality good moonshine, heating must be done in stages. There are also key distillation points to watch out for.

1. Selection of volatile fractions. Evaporation of harmful volatile fractions, such as methyl alcohol, acetaldehyde, formic-ethyl ether, occurs when the mash is heated to 65-68 ° C. At this stage, an alcoholic smell and drops of condensed liquid appear. The moonshine obtained as a result of this stage is popularly called "pervach". This liquid is poisonous and not suitable for consumption. This first fraction is collected in a separate container and subsequently used for technical needs. Braga is heated on maximum heat until the temperature reaches 63 ° C. After that, the fire is reduced. This moment is very important, it should never be missed. Otherwise, the wash can get into various parts of the moonshine still. In this case, the quality, taste and color of the drink will noticeably deteriorate.

2. The main distillation process. At this stage, it is necessary to change the steamer (if any), substitute the container where the moonshine will be collected, and gradually bring the liquid to 78 ° C - the temperature at which the distillation begins. After some time, the release of the main product will begin. We must not forget that the concentration of alcohol in the liquid will decrease, which will lead to an increase in the boiling point and deterioration of the distillation conditions. At this stage, the ideal temperature is 78-83 ° C. When the liquid reaches a temperature of 85 ° C, the fusel oils begin to evaporate, which makes the moonshine cloudy and deteriorates its quality. In the absence of a thermometer, the main process is stopped in the following cases: -the paper, which is soaked in moonshine, does not burn with a blue flame; -output drops to 0; - the strength of the drink is below 40 degrees

3. Selection of the last faction. At temperatures above 85 ° C, the distillate is already collected in a separate container. This faction, like the first one, is called “heads”. It is sometimes added to the main product to increase its strength. Fusel oils are also distinguished here.

There is another method of making moonshine - freezing. It is based on the freezing point difference between water and alcohol. This method is laborious and ineffective in comparison with traditional distillation.

So, the mash is ripe for distillation, clarified and removed from the sediment (see), it's time to distill the moonshine. By this time, you should already have a moonshine still. It is best to arm yourself with a factory apparatus such as moonshine still "Magarych", It has a high performance, there is a steam chamber and a thermometer, which is very important for the production of high quality. Moreover, this apparatus is absolutely sealed and made using seamless technology, which ensures safe distillation of the mash into moonshine. Yes, and for the price - what you need if you are not a Rockefeller.

Technology of distillation of mash into moonshine

Pour the mash into the distillation container, by ¾ the volume of the container, no more. The alembic should be well washed. Check all connections before you start distilling the mash and put it on fire. Screw the neck of the distillation container tightly.

If you have, then coat the neck with dough, for insurance, and keep a cup of dough at the ready if it suddenly starts to pass steam. Put the apparatus on high heat until the mash begins to boil. As soon as the wash starts to boil (about 75 0 С, if there is a thermometer built into the device), you can determine by the heating of the steam outlet hose, turn on the cold water through the hose going to the cooler. Place a can under the nipple from which the moonshine should drip. As soon as the first drops begin to drip, reduce the heat to low.

Ethyl alcohol boils at a temperature of 78.8 0 C, but even earlier (65-78 0 C) light fractions begin to boil and enter the coil and methyl alcohol is poison! It needs to be poured out of the can. If there is a thermometer, then everything that goes into the jar up to 78.8 0 С must be poured out. If there is no thermometer, then fold the first 30 grams of distillate.

The heating temperature must not be exceeded. Firstly, it is dangerous - it can explode.

Secondly, the mash will immediately begin to actively boil and it will be thrown into the coil, as well as the emission of harmful impurities will increase. You will see this immediately, as whitish drops, sweetish in taste, begin to drip. To prevent the mash from escaping into the hose leading to the coil, you can pour 0.5 liters of milk into the mash.

First, alcohol will be supplied to the jar, with a strength of 65-70 0, which will gradually weaken.

Keep track of the strength of the ferrying mash - moonshine and the temperature of the mash. As soon as the temperature of the mash reached 85-87 0 С, and the strength of the distillation decreased to 30 0, fusel oils begin to flow intensively and the distillation of the mash must be stopped, and the remaining mash must be poured out.

Here is a video on the topic of how to distill the mash into moonshine:

Re-distillation of moonshine

To maximally clean the moonshine from fusel oils, improve the taste and get rid of the unpleasant odor, it must be distilled again. When distilling mash into moonshine, mash and yeast are involved in the reaction, so the product has some taste and a specific smell. During the re-distillation of moonshine, the main participant is alcohol and almost no yeast.

Add a little potassium permanganate (potassium permanganate) to the moonshine diluted to 20 0, so that it itself becomes slightly pink.

Wait until the manganese settles to the bottom, and remove the moonshine from the sediment (using a hose with a suction), strain through cheesecloth.

Making alcohol at home is fun and creative. Both the process and the result, and even the study of the topic bring pleasure to home distillers. But you need to follow certain rules so as not to get a dangerous product. And for this you need to correctly select the fractions in our drink. After all, they contain dangerous compounds.

Moonshine fractions

It does not matter from what raw material the mash is prepared, all the same, during the heating process, substances harmful to the human body will be released from it. They are usually called "fusel oils", although this is not a completely correct definition. To keep them as small as possible in the moonshine, it is necessary to separate the first, second and third fractions. They are uneven in volume, strength, composition.

- The head fraction or "head" appears in the tank first. People call it "pervach" and consider it the most valuable, but this is not so. It is as strong and incredibly harmful as possible - it can only be used for technical purposes. If you separate it with a margin, you need to waste 50 grams for each kilo of sugar.

- The center or "body" is a relatively pure alcohol.

- The residual part from home brewing or "tails" also contains a lot of impurities, but the tails in the moonshine are subject to processing. They can also be used to make the next batch of wort.

How it works in practice

Important: we measure the strength of portions precisely at t = + 20 ° С!

- Now "tails" will come. They need to be driven until t of the mash reaches + 98.7 ° C. At this temperature, there is almost no alcohol in the raw materials. Then the water will begin to evaporate, and all we can achieve is to reduce the concentration of alcohol in the last fraction. The tail can be purified and re-sent for distillation.

Theoretical basis

To know how to properly select heads and residual fraction, you need to understand why this is done. Let's take a look at the physics of our home distillation.

To know how to properly select heads and residual fraction, you need to understand why this is done. Let's take a look at the physics of our home distillation.

Obviously, during the subsequent distillation, they will again break free before alcohol (it just turns into steam at + 78.4 ° C) and will again be present in the distillate. Therefore, the heads should be separated during the first and subsequent distillations. Here, savings can lead to dire consequences.

Let's summarize

To split the resulting moonshine into fractions and remove the "heads" and "tails", special efforts and equipment are not needed. But at the same time, we will get rid of very harmful impurities and protect ourselves and our friends. And the concentration of "fusel oils" without selection can be tens (!) Times higher than the permissible one.