Leveling walls and ceilings with putty is probably the best way to achieve perfect evenness of the surface for further finishing. Even in the situation when drywall sheets are used to create even planes, in most cases it is not possible without finishing “polishing” with putty. This process is not as simple as it might seem. at first sight, but still it does not seem impossible with diligence, following technological recommendations and gradually gaining experience by a novice master.

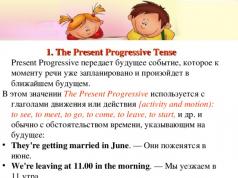

putty prices

putty

The range of ready-made compositions or dry building mixes for performing these finishing operations is very wide, that is, there should be no problems with the choice. But the question is - how much material needs to be purchased so as not to run to the store again, and so that after the repair there is not too much surplus left? And the "other side of the coin" - most putty compositions are characterized by a very limited "lifetime" after dilution. That is, already in the course of work, it is desirable to know how much composition needs to be prepared for a specific section of the wall or ceiling in order to ensure that the mortar is worked out and avoid unnecessary waste. In both cases, a calculator for calculating the required amount of putty should come to the rescue.

A few necessary explanations for working with it will be given below.

Calculator for calculating the required amount of putty

Putty is a special mixture that contains binders and additives. Its main function is to level the surface of walls and ceilings before performing decorative work. With the help of the mixture, deep and small cracks are eliminated, a base layer is created for better adhesion to the finish coating - wallpaper and other elements. Before starting repairs, you need to take into account the features of the main building materials, atmospheric parameters of the environment, in order to determine the best putty for the job.

There are several mass options. The amount of substance that is necessary for finishing work depends on the type of mixture. Putty consumption is calculated per square meter in kilograms:

- for adhesive - 0.47;

- for plaster - 0.85;

- for the finish line - 0.44;

- for Shitrok - 1;

- for vetonite - 1, 18;

- for the facade - from 1.18 to 1.6;

At the same time, it is important to take into account not only the rate of putty consumption per 1 m2, the composition of the solution, but also the properties of the material on which the mixture will be applied. This data is required for the slurry flow calculator.

Factors Affecting Material Costs

In most cases, consumption rates are indicative. The approximate amount will tell the professional who plans the repair. However, it is often necessary to purchase additional putty in the future. To take the right amount of the mixture, you need to pay attention to the instructions for use.

The weight of the material indicated on the package reflects how much composition is required to work. It is designed for perfectly smooth surfaces. In practice, it is always better to have a margin, taking into account the characteristics of the walls of the room and other factors. The following reasons for the increased consumption of putty per 1 m2 of wall can be noted.

- The quality of the building materials of the building - the presence of irregularities and roughness, the depth of cracks on the surface.

- Partial residue of the mixture on the inner walls of the container for mixing putty.

- The technique of diluting the putty mass.

- Putty application technique.

- The rate of distribution of the finished product.

The quality of putty application involves the application of layers of a certain thickness. If you exceed the recommended volume, then after drying, there is a possibility that the mass will crumble. This will require correction of repairs and additional material costs. Usually the solution is applied twice. The first layer should not exceed 8 mm. The second time, when calculating the putty, the thickness should be less - about 3 mm. The preservation of wall defects indicates poor-quality plastering work.

For the optimal consumption of putty, it is necessary to adhere to the rules for diluting the suspension.

- It is better to use small containers for preparing the mass, because the mixture hardens within one hour.

- It is not necessary to knead the solution to a homogeneous structure. Small lumps in the process will acquire the necessary consistency.

- The container should be thoroughly washed after each serving of putty. The remains of the previous putty accelerate the hardening of the working mass.

Attention! During repairs, experienced craftsmen do not recommend kneading more than 4 kilograms of dry matter.

Putty consumption calculator 1 meter wall

In construction stores, mixtures of various composition and structure are presented. The manufacturer often offers dry masses that are diluted with water. A good alternative is a ready-made product that is easy to use. The liquid formula does not require dilution and is more economical to use.

Before you buy a mixture, you should prepare - make the necessary measurements and spend the putty on 1 m2 of wall. The calculator is presented as follows. Pre-calculate the area of \u200b\u200bthe walls and ceilings that will be processed. Then specify the rate of material consumption per square meter. The data is displayed in the application instructions. The next indicator is the layer thickness. The product of three parameters forms an indicator of the mass of the solution required for repair. In this case, one layer is conventionally assumed to be one millimeter wide.

The process of preparing the mixture takes into account the brand of putty and its composition

Important! Continuous leveling requires, according to different options, from 900 to 2 kg of substance.

First, apply the starting layer. For a dry mix, an average of 400 ml of cold temperature water is needed. The finished putty should be pasty. For the first time it is necessary to apply a layer with a thickness of approximately 5 mm. In this case, the consumption ranges from 1 kg 200 g to 1 kg 800 g per square meter of surface. If the surfaces are uneven, the base layer will vary in size in different places. The final layer is more liquid. When diluted with water, one kilogram dissolves in 500 - 600 ml. The mixture for leveling will need half as much.

Recently, universal solutions have been very popular, which can be used as a base coat, as well as for final work. The thickness of the layers applied to the surface does not exceed 4 mm.

The correct calculation and consumption of putty allows you to save time and money when carrying out repairs of any complexity.

As you know, putty is a special building mass from a binder component and various additives. It is used before applying the finish for rubbing plaster, sealing joints and final leveling of walls with minor height differences, usually from 1 mm to 2 cm. Traditionally, the putty layer is located between the plaster and the finishing decor.

Thanks to putty, the wall becomes strong, smooth, without bumps and various flaws, with a beautiful appearance, while wallpaper or new paint will last you much longer. You can buy putty both in the form of a dry mixture, which is closed with water, and in the form of a ready-made putty mass. The consumption rate of putty per 1 m2 is from 1 to 1.5 kg. per 1 mm layer. depending on the type of mixture.

Preparatory work

Before the beginning work, the question naturally arises: how much putty will be needed for repairs and what does its consumption depend on? Suppose the work is coming to an end, but in the end it turns out that at least a little putty was not enough. Or another situation: putty is done by a work team that will give you an overestimate when you have to buy too much. Here, in order not to get into such situations, you need to understand the features of the rationing of building materials.

Putty consumption primarily depends on its type: each type of putty mass is consumed differently. You also need to take into account the condition of the treated surface, which affects the thickness of the putty layer. Among other nuances that affect the consumption of the material, one can single out the correct preparation of the mixture, as well as the quality of the putty application.

Now there are three basic types of putty, on which the consumption rates of building materials directly depend: starting, universal and finishing.

Starting putty - consumption per 1 m2.

For the initial leveling of the base, a starting putty is used. It is applied as an intermediate coating between plaster and finishing putty. At the same time, the starting putty incorporates a rather coarse fraction, since it is most often based on gypsum or lime. Therefore, its consumption will be the largest. Starting putty is sold in paper packages of 25 and 30 kg.

The consumption of the starting putty composition usually averages 1.0-1.4 kg per “square” of the base with a layer of 1 mm. More details about this information are given in the instructions.

It has been verified by practice that one standard bag for 30 kg of any starting putty with minimal irregularities, and even for a paint grid, is quite enough for 10-20 square meters. m walls.

But if the walls are in poor condition and not leveled, then the consumption of putty mixture will increase. For example, if a layer of starting putty is planned to be 5 mm, then its consumption will increase to approximately 4-8 kg per square meter. m.

Features of the consumption of starting putty

An important point should be taken into account: it is not recommended to apply a starting putty composition thicker than 5-10 mm in one pass, otherwise it may crumble in the future. The description for any putty usually indicates the minimum and maximum allowable level of the layer at a time.

For example, for Polimin ShG-11 putty, the calculated thickness at a time is taken not less than 3 mm, but not more than 10 mm. Composition yield: 1.05 kg per "square" with a layer of 1 mm.

But the SATYN PW-01 putty has a maximum allowable layer thickness of 8 mm, consumption per sq. m. is 1.3 kg.

The instructions for the starting polymer cement putty "Ceresit CT 29" indicate that the thickness of the application of one layer varies from 2 to 20 mm, and in fact, the consumption of this mixture per square meter. meter goes 1.8 kg with a millimeter layer

ADVICE! In order to minimize the cost of building materials and not exceed the allowable limits, it is advisable to study the surface in advance and, if necessary, plaster old, rough and too uneven walls.

By the way, in the form of an initial leveling composition, you can also choose the popular starting mixture "Knauf HP Start" based on lime and gypsum. It is very comfortable and suitable both in the form of plaster and in the form of starting putty. The declared borders of the smearing are 1-3 cm. With a solution thickness of 10 mm, a 30-kg package of the mixture is enough for 3.8-4.0 sq.m.

Apply finishing putty at a time you need the thinnest layer, usually 0.2-1.5 mm, otherwise it can “swim” and crack. Containers weighing 17 kg will be enough for you for 35-40 square meters. m walls.

In addition to the finished mass, dry mixes like Vetonit LR + based on special polymer components are used for the final leveling of the walls. It is sold in a 25-kg package. The consumption of finishing "vetonite" is 1.2 kg per unit area with a layer of 1 mm. Puttying here can be thicker: the thickness of one laying of the mixture per pass is taken within 1-5 mm.

Or here's another alternative - putty "Knauf Satengips finishing" in a 25-kg bag with the minimum possible layer of 0.2 mm, the maximum - 5 mm. Consumption: 1 kg of composition per "square" of the wall with a millimeter layer thickness.

As you can see, in different manufacturers putty consumption rates are different. In order not to be mistaken, especially with a shortage of building materials, take the initial parameters of the mixture consumption on the package, multiply them by the area of the wall being processed and add 15% to the result. Accordingly, if the putty layer is planned to be more than 1 millimeter, multiply everything by the desired thickness factor and as a result you will get the right amount of material.

Tips for preparing putty mortar

When preparing putty from a dry mixture, follow all the recommendations of the instructions: you need to add water in a given proportion, use clean containers, mix correctly, make intervals so that the mixture is a little infused, make sure that foreign objects do not get there, etc. An improperly prepared mixture does not will only increase the consumption of building materials, but may lead to poor quality repairs. Also remember about the density of the mixture. If it is necessary to even out fairly significant irregularities, then the putty should be closed to a thicker consistency. In this case, the consumption of the composition per unit area will be greater.

Finally, the flow rate of the mixture also depends on putty application quality. In particular, novice craftsmen often sin with some overspending of building materials. Of course, in general, do-it-yourself putty will cost much less than hiring a repair team: buying another bag is not so scary for your pocket as paying a premium to an outside foreman. But there may be a risk of inadequate quality of work. Therefore, if you putty on your own, carefully follow the technology and sequence of work. Specialists of the construction company puttyed thousands of square meters of walls and ceilings, and they will do it qualitatively when carrying out repairs in your home!