BUT. G. Semenov, general director, joint venture "Elkon", G. Chisinau; L. P. Sysa, leading engineer on ECP, NPC "Vector", G. Moscow

Introduction

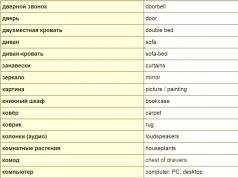

Cathodic Protection Stations (CPS) are necessary element electrochemical (or cathodic) protection systems (ECP) underground pipelines from corrosion. When choosing VHCs, they most often proceed from lowest cost, serviceability and qualification of its service personnel. The quality of the purchased equipment is usually difficult to assess. The authors propose to consider the data indicated in the passports technical specifications RMS, which determine how well the main task of cathodic protection will be performed.

The authors did not intend to express themselves strictly scientific language in defining concepts. In the process of communicating with the personnel of the ECP services, we realized that it is necessary to help these people systematize the terms and, more importantly, give them an idea of what is happening both in the power grid and in the VCS itself.

A taskECP

cathodic protection is carried out when an electric current flows from the SKZ along a closed electrical circuit, formed by three resistors connected in series:

· soil resistance between pipeline and anode; I anode spreading resistance;

pipeline insulation resistance.

The soil resistance between the pipe and the anode can vary widely depending on the composition and external conditions.

The anode is an important part of the ECP system, and serves as the consumable element, the dissolution of which provides the very possibility of ECP implementation. Its resistance during operation steadily increases due to dissolution, a decrease in the effective area of the working surface and the formation of oxides.

Consider the metal pipeline itself, which is the protected element of the ECP. The metal pipe is covered with insulation on the outside, in which cracks form during operation due to mechanical vibrations, seasonal and daily temperature changes, etc. Moisture penetrates through the cracks in the hydro- and thermal insulation of the pipeline and the metal of the pipe contacts the ground, thus forming a galvanic couple that contributes to the removal of metal from the pipe. The more cracks and their size, the more metal is taken out. Thus, galvanic corrosion occurs, in which a current of metal ions flows, i.e. electricity.

Since the current is flowing, then a wonderful idea arose to take an external current source and turn it on to meet this very current, due to which the removal of metal and corrosion occurs. But the question arises: what is the magnitude of this most man-made current to give? It seems to be such that plus to minus gives zero metal removal current. And how to measure this same current? The analysis showed that the tension between metal pipe and soil, i.e. on both sides of the insulation, must be between -0.5 and -3.5 V (this voltage is called the protective potential).

A taskVHC

The task of the SKZ is not only to provide current in the ECP circuit, but also to maintain it in such a way that the protective potential does not go beyond the accepted limits.

So, if the insulation is new, and it has not had time to get damaged, then its resistance electric current high and need a small current to maintain the desired potential. As the insulation ages, its resistance decreases. Consequently, the required compensating current from the RMS increases. It will increase even more if cracks appear in the insulation. The station must be able to measure the protective potential and change its output current accordingly. And nothing more, from the point of view of the ECP task, is required.

ModesworkVHC

There are four modes of operation of the ECP:

without stabilization of output values of current or voltage;

I stabilize the output voltage;

stabilization of the output current;

· I stabilization of the protective potential.

Let's say right away that in the accepted range of changes of all influencing factors, the fulfillment of the ECP task is fully ensured only when using the fourth mode. Which is accepted as the standard for the operating mode of the SKZ.

The potential sensor gives the station information about the potential level. The station changes its current in the right direction. Problems begin from the moment when it is necessary to put this very potential sensor. You need to put it in a certain calculated place, you need to dig a trench for the connecting cable between the station and the sensor. Anyone who laid any communications in the city knows what a hassle it is. Plus, the sensor requires periodic maintenance.

In conditions where there are problems with the mode of operation with feedback Potentially, proceed as follows. When using the third mode, it is assumed that the state of the insulation changes little in the short term and its resistance remains practically stable. Therefore, it is enough to ensure the flow of a stable current through a stable insulation resistance, and we get a stable protective potential. In the medium and long term, the necessary adjustments can be made by a specially trained lineman. The first and second regimes do not impose high requirements on the SKZ. These stations are simple in execution and, as a result, cheap, both in manufacture and in operation. Apparently, this circumstance determines the use of such SCs in the ECP of objects located in conditions of low corrosive activity of the environment. If external conditions(state of insulation, temperature, humidity, stray currents) change to the limits when an unacceptable mode is formed on the protected object - these stations cannot perform their task. To adjust their mode, the frequent presence of maintenance personnel is necessary, otherwise the ECP task is partially performed.

CharacteristicsVHC

First of all, the VHC must be selected based on the requirements set out in normative documents. And, probably, the most important thing in this case will be GOST R 51164-98. Appendix "I" of this document states that the efficiency of the station must be at least 70%. The level of industrial noise generated by RMS should not exceed the values specified by GOST 16842, and the level of harmonics at the output should comply with GOST 9.602.

The SKZ passport usually indicates: I rated output power;

Efficiency at rated output power.

Rated output power - the power that the station can deliver at rated load. Typically this load is 1 ohm. The efficiency is defined as the ratio of the rated output power to the active power consumed by the station in the rated mode. And in this mode, the efficiency is the highest for any station. However, most VCSs operate far from the nominal mode. The power load factor ranges from 0.3 to 1.0. In this case, the real efficiency for most stations manufactured today will drop noticeably with a decrease in output power. This is especially noticeable for transformer SKZ using thyristors as a regulating element. For transformerless (high-frequency) RMS, the drop in efficiency with a decrease in output power is much less.

A general view of the change in efficiency for SKZ of different designs can be seen in the figure.

From fig. it can be seen that if you use the station, for example, with a nominal efficiency of 70%, then be prepared for the fact that you have spent another 30% of the electricity received from the network uselessly. And this is in the best case of rated output power.

With an output power of 0.7 of the nominal, you should already be prepared for the fact that your energy losses will be equal to the useful energy spent. Where is so much energy being wasted?

ohmic (thermal) losses in the windings of transformers, chokes and active elements of the circuit;

· energy costs for the operation of the station control circuit;

Loss of energy in the form of radio emission; energy losses of the output current ripple of the station at the load.

This energy is radiated into the ground from the anode and does not produce useful work. Therefore, it is so necessary to use stations with a low ripple coefficient, otherwise expensive energy is wasted. Not only that, at high levels of ripples and radio emission, power losses increase, but besides this, this uselessly dissipated energy interferes with normal operation. a large number electronic equipment located in the vicinity. The required total power is also indicated in the SKZ passport, let's try to deal with this parameter. The SKZ takes energy from the power grid and does it in every unit of time with such intensity as we have allowed it to do with the adjustment knob on the control panel of the station. Naturally, it is possible to take energy from the network with a power not exceeding the power of this network itself. And if the voltage in the network changes sinusoidally, then our ability to take energy from the network changes sinusoidally 50 times per second. For example, at the moment when the mains voltage passes through zero, no power can be taken from it. However, when the voltage sinusoid reaches its maximum, then at this moment our ability to take energy from the network is maximum. At any other time, this possibility is less. Thus, it turns out that at any time the power of the network differs from its power at a neighboring time. These power values are called instantaneous power in this moment time and such a concept is difficult to operate. Therefore, we agreed on the concept of the so-called effective power, which is determined from an imaginary process in which a network with a sinusoidal voltage change is replaced by a network with a constant voltage. When we calculated the value of this constant voltage for our electrical networks, we got 220 V - it was called the effective voltage. BUT maximum value the sinusoids of the voltage were called the amplitude voltage, and it is equal to 320 V. By analogy with the voltage, the concept of the effective value of the current was introduced. The product of the effective voltage value and the effective current value is called the total power consumption, and its value is indicated in the RMS passport.

And the full power in the SKZ itself is not fully used, because. it has various reactive elements that do not waste energy, but use it, as it were, to create conditions for the rest of the energy to pass into the load, and then return this tuning energy back to the network. This energy returned back was called reactive energy. The energy that is transferred to the load is active energy. The parameter that indicates the ratio between the active energy that must be transferred to the load and the total energy supplied to the RMS is called the power factor and is indicated in the station passport. And if we coordinate our capabilities with the capabilities of the supply network, i.e. synchronously with a sinusoidal change in the voltage of the network, we take power from it, then such a case is called ideal and the power factor of the RMS operating with the network in this way will be equal to one.

The station must transmit active energy as efficiently as possible to create a protective potential. The efficiency with which the VHC does this is assessed by the coefficient useful action. How much energy it spends depends on the method of energy transfer and on the mode of operation. Without going into this vast field for discussion, we will only say that transformer and transformer-thyristor SKZs have reached their limit of improvement. They do not have the resources to improve the quality of their work. The future belongs to high-frequency VMS, which every year become more reliable and easier to maintain. In terms of efficiency and quality of their work, they already surpass their predecessors and have a large reserve for improvement.

Consumerproperties

The consumer properties of such a device as SKZ include the following:

1. Dimensions, the weight and strength. Probably, it is not necessary to say that the smaller and lighter the station, the lower the cost of its transportation and installation, both during installation and repair.

2. maintainability. The ability to quickly replace a station or node on site is very important. With subsequent repairs in the laboratory, i.e. modular principle of construction of SKZ.

3. Convenience in service. Ease of maintenance, in addition to ease of transportation and repair, is determined, in our opinion, as follows:

the presence of all necessary indicators and measuring instruments, the possibility of remote control and monitoring the operation of the SKZ.

conclusions

Based on the foregoing, several conclusions and recommendations can be drawn:

1. Transformer and thyristor-transformer stations are hopelessly outdated in all respects and do not meet modern requirements, especially in the field of energy saving.

2. A modern station must have:

· high efficiency in all range of loadings;

power factor (cos I) not less than 0.75 in the entire load range;

output voltage ripple factor no more than 2%;

· current and voltage regulation range from 0 to 100%;

lightweight, durable and small-sized body;

· modular principle of construction, i.e. have high maintainability;

· I energy efficiency.

Other requirements for cathodic protection stations, such as protection against overloads and short circuits; automatic maintenance of a given load current - and other requirements are generally accepted and mandatory for all SKZ.

In conclusion, we offer consumers a table comparing the parameters of the main manufactured and currently used cathodic protection stations. For convenience, the table shows stations of the same power, although many manufacturers can offer a whole range of manufactured stations.

| Parameter name | Meaning |

| Article subject: | cathodic protection |

| Rubric (thematic category) | Industry |

cathodic protection that - the most widespread type of electrochemical protection. It is used in cases where the metal is not prone to passivation, that is, it has an extended region of active dissolution, a narrow passive region, high passivation current (i p) and passivation potential (c p).

Cathodic polarization can be carried out by connecting the structure to be protected to the negative pole of an external current source. Cathodic protection is carried out by an external current. .

The scheme of cathodic protection is shown in fig. 4. The negative pole of the external current source 4 is connected to the protected metal structure 1, and the positive pole is connected to the auxiliary electrode 2, which acts as an anode. In the process of protection, the anode is actively destroyed and is subject to periodic restoration.

Cast iron, steel, coal, graphite, scrap metal (old pipes, rails, etc.) are used as the anode material. The sources of external current in cathodic protection are cathodic protection stations, the mandatory elements of which are: a converter (rectifier) that generates current; current supply to the structure to be protected, reference electrode, anode earth electrodes, anode cable.

Cathodic protection of factory equipment (refrigerators, heat exchangers, condensers, etc.) exposed to an aggressive environment is carried out by connecting an external current source to the negative pole and immersing the anode in this environment.

Cathodic protection by external current is impractical under conditions of atmospheric corrosion, in a vaporous environment, in organic solvents, since in this case corrosive environment does not have sufficient electrical conductivity.

Protective protection. Protective protection is a type of cathodic protection. The scheme of the protective protection of the pipeline is shown in fig. 5. A more electronegative metal is attached to the protected structure 2 - protector 3, which, dissolving in the environment, protects the main structure from destruction.

After complete dissolution of the protector or loss of contact with the protected structure, it is extremely important to replace the protector.

Figure 5 Scheme of the protective protection of the pipeline

The protector works effectively if the contact resistance between it and the environment is small. During operation, the protector, for example, zinc, can be covered with a layer of insoluble corrosion products, which isolate it from environment and sharply increase the transient resistance. To combat this, the protector is placed in filler 4 - a mixture of salts, which creates a certain environment around it, which facilitates the dissolution of corrosion products and increases the efficiency and stability of the protector in the ground.

Protective protection, compared with cathodic protection by external current, is advisable to use in cases where obtaining energy from the outside is difficult or if the construction of special power lines is not economically viable.

Today, tread protection is used to combat corrosion of metal structures in sea and river water, soil and other neutral media. The use of tread protection in acidic environments limited by the high self-dissolution rate of the tread.

Metals can be used as protectors: Al, Fe, Mg, Zn. At the same time, it is not always advisable to use pure metals as protectors. To give the protectors the required performance properties, alloying elements are introduced into their composition.

Cathodic protection - concept and types. Classification and features of the cathodic protection category 2017, 2018.

Cathodic protection stations (CPS) are a necessary element of the system of electrochemical (or cathodic) protection (ECP) of underground pipelines against corrosion. When choosing a VCS, they most often proceed from the lowest cost, ease of maintenance and qualifications of their service personnel. The quality of the purchased equipment is usually difficult to assess. The authors propose to consider the technical parameters of the CPS indicated in the passports, which determine how well the main task of cathodic protection will be performed.

The authors did not pursue the goal of expressing themselves in a strictly scientific language in the definition of concepts. In the process of communicating with the personnel of the ECP services, we realized that it is necessary to help these people systematize the terms and, more importantly, give them an idea of what is happening both in the power grid and in the VCS itself.

ECP task

Cathodic protection is carried out when an electric current flows from the RMS through a closed electrical circuit formed by three resistors connected in series:

· soil resistance between pipeline and anode; I anode spreading resistance;

pipeline insulation resistance.

The soil resistance between the pipe and the anode can vary widely depending on the composition and external conditions.

The anode is an important part of the ECP system, and serves as the consumable element, the dissolution of which provides the very possibility of ECP implementation. Its resistance during operation steadily increases due to dissolution, a decrease in the effective area of the working surface and the formation of oxides.

Consider the metal pipeline itself, which is the protected element of the ECP. The metal pipe is covered with insulation on the outside, in which cracks form during operation due to mechanical vibrations, seasonal and daily temperature changes, etc. Moisture penetrates through the cracks in the hydro- and thermal insulation of the pipeline and the metal of the pipe contacts the ground, thus forming a galvanic couple that contributes to the removal of metal from the pipe. The more cracks and their sizes, the more metal is carried out. Thus, galvanic corrosion occurs, in which a current of metal ions flows, i.e. electricity.

Since the current is flowing, then a wonderful idea arose to take an external current source and turn it on to meet this very current, due to which the removal of metal and corrosion occurs. But the question arises: what is the magnitude of this most man-made current to give? It seems to be such that plus to minus gives zero metal removal current. And how to measure this same current? The analysis showed that the voltage between the metal pipe and the ground, i.e. on both sides of the insulation, must be between -0.5 and -3.5 V (this voltage is called the protective potential).

The task of the VHC

The task of the SKZ is not only to provide current in the ECP circuit, but also to maintain it in such a way that the protective potential does not go beyond the accepted limits.

So, if the insulation is new, and it has not had time to get damaged, then its resistance to electric current is high and a small current is needed to maintain the desired potential. As the insulation ages, its resistance decreases. Consequently, the required compensating current from the RMS increases. It will increase even more if cracks appear in the insulation. The station must be able to measure the protective potential and change its output current accordingly. And nothing more, from the point of view of the ECP task, is required.

SKZ operating modes

There are four modes of operation of the ECP:

without stabilization of output values of current or voltage;

I stabilize the output voltage;

stabilization of the output current;

· I stabilization of the protective potential.

Let's say right away that in the accepted range of changes of all influencing factors, the fulfillment of the ECP task is fully ensured only when using the fourth mode. Which is accepted as the standard for the operating mode of the SKZ.

The potential sensor gives the station information about the potential level. The station changes its current in the right direction. Problems begin from the moment when it is necessary to put this very potential sensor. You need to put it in a certain calculated place, you need to dig a trench for the connecting cable between the station and the sensor. Anyone who laid any communications in the city knows what a hassle it is. Plus, the sensor requires periodic maintenance.

In conditions where there are problems with the potential feedback mode, proceed as follows. When using the third mode, it is assumed that the state of the insulation changes little in the short term and its resistance remains practically stable. Therefore, it is enough to ensure the flow of a stable current through a stable insulation resistance, and we get a stable protective potential. In the medium and long term, the necessary adjustments can be made by a specially trained lineman. The first and second regimes do not impose high requirements on the SKZ. These stations are simple in execution and, as a result, cheap, both in manufacture and in operation. Apparently, this circumstance determines the use of such SCs in the ECP of objects located in conditions of low corrosive activity of the environment. If the external conditions (state of insulation, temperature, humidity, stray currents) change to the limits when an unacceptable mode is formed on the protected object, these stations cannot perform their task. To adjust their mode, the frequent presence of maintenance personnel is necessary, otherwise the ECP task is partially performed.

Characteristics of SKZ

First of all, the SKZ must be selected based on the requirements set forth in the regulatory documents. And, probably, the most important thing in this case will be GOST R 51164-98. Appendix "I" of this document states that the efficiency of the station must be at least 70%. The level of industrial noise generated by RMS should not exceed the values specified by GOST 16842, and the level of harmonics at the output should comply with GOST 9.602.

The SKZ passport usually indicates: I rated output power;

Efficiency at rated output power.

Rated output power - the power that the station can deliver at rated load. Typically this load is 1 ohm. The efficiency is defined as the ratio of the rated output power to the active power consumed by the station in the rated mode. And in this mode, the efficiency is the highest for any station. However, most VCSs operate far from the nominal mode. The power load factor ranges from 0.3 to 1.0. In this case, the real efficiency for most stations manufactured today will drop noticeably with a decrease in output power. This is especially noticeable for transformer SKZ using thyristors as a regulating element. For transformerless (high-frequency) RMS, the drop in efficiency with a decrease in output power is much less.

A general view of the change in efficiency for SKZ of different designs can be seen in the figure.

From fig. it can be seen that if you use the station, for example, with a nominal efficiency of 70%, then be prepared for the fact that you have spent another 30% of the electricity received from the network uselessly. And this is in the best case of rated output power.

With an output power of 0.7 of the nominal, you should already be prepared for the fact that your energy losses will be equal to the useful energy spent. Where is so much energy being wasted?

ohmic (thermal) losses in the windings of transformers, chokes and active elements of the circuit;

· energy costs for the operation of the station control circuit;

Loss of energy in the form of radio emission; energy losses of the output current ripple of the station at the load.

This energy is radiated into the ground from the anode and does not produce useful work. Therefore, it is so necessary to use stations with a low ripple coefficient, otherwise expensive energy is wasted. Not only that, at high levels of ripples and radio emission, the loss of electricity increases, but besides this, this uselessly dissipated energy interferes with the normal operation of a large number of electronic equipment located in the vicinity. The required total power is also indicated in the SKZ passport, let's try to deal with this parameter. The SKZ takes energy from the power grid and does it in every unit of time with such intensity as we have allowed it to do with the adjustment knob on the control panel of the station. Naturally, it is possible to take energy from the network with a power not exceeding the power of this network itself. And if the voltage in the network changes sinusoidally, then our ability to take energy from the network changes sinusoidally 50 times per second. For example, at the moment when the mains voltage passes through zero, no power can be taken from it. However, when the voltage sinusoid reaches its maximum, then at this moment our ability to take energy from the network is maximum. At any other time, this possibility is less. Thus, it turns out that at any time the power of the network differs from its power at a neighboring time. These power values are called instantaneous power at a given time and it is difficult to operate with such a concept. Therefore, we agreed on the concept of the so-called effective power, which is determined from an imaginary process in which a network with a sinusoidal voltage change is replaced by a network with a constant voltage. When we calculated the value of this constant voltage for our electrical networks, we got 220 V - it was called the effective voltage. And the maximum value of the sinusoid of the voltage was called the amplitude voltage, and it is equal to 320 V. By analogy with the voltage, the concept of the effective value of the current was introduced. The product of the effective voltage value and the effective current value is called the total power consumption, and its value is indicated in the RMS passport.

And the full power in the SKZ itself is not fully used, because. it has various reactive elements that do not waste energy, but use it, as it were, to create conditions for the rest of the energy to pass into the load, and then return this tuning energy back to the network. This energy returned back was called reactive energy. The energy that is transferred to the load is active energy. The parameter that indicates the ratio between the active energy that must be transferred to the load and the total energy supplied to the RMS is called the power factor and is indicated in the station passport. And if we coordinate our capabilities with the capabilities of the supply network, i.e. synchronously with a sinusoidal change in the voltage of the network, we take power from it, then such a case is called ideal and the power factor of the RMS operating with the network in this way will be equal to one.

The station must transmit active energy as efficiently as possible to create a protective potential. The efficiency with which the VHC does this is evaluated by the efficiency factor. How much energy it spends depends on the method of energy transfer and on the mode of operation. Without going into this vast field for discussion, we will only say that transformer and transformer-thyristor SKZs have reached their limit of improvement. They do not have the resources to improve the quality of their work. The future belongs to high-frequency VMS, which every year become more reliable and easier to maintain. In terms of efficiency and quality of their work, they already surpass their predecessors and have a large reserve for improvement.

Consumer properties

The consumer properties of such a device as SKZ include the following:

1. Dimensions, weight and strength. Probably, it is not necessary to say that the smaller and lighter the station, the lower the cost of its transportation and installation, both during installation and repair.

2. Maintainability. The ability to quickly replace a station or node on site is very important. With subsequent repairs in the laboratory, i.e. modular principle of construction of SKZ.

3. Ease of maintenance. Ease of maintenance, in addition to ease of transportation and repair, is determined, in our opinion, as follows:

the presence of all the necessary indicators and measuring instruments, the possibility of remote control and monitoring of the operating mode of the SKZ.

Based on the foregoing, several conclusions and recommendations can be drawn:

1. Transformer and thyristor-transformer stations are hopelessly outdated in all respects and do not meet modern requirements, especially in the field of energy saving.

2. A modern station must have:

· high efficiency in all range of loadings;

power factor (cos I) not less than 0.75 in the entire load range;

output voltage ripple factor no more than 2%;

· current and voltage regulation range from 0 to 100%;

lightweight, durable and small-sized body;

· modular principle of construction, i.e. have high maintainability;

· I energy efficiency.

Other requirements for gas pipeline cathodic protection stations, such as protection against overloads and short circuits; automatic maintenance of a given load current - and other requirements are generally accepted and mandatory for all SKZ.

In conclusion, we offer consumers a table comparing the parameters of the main manufactured and currently used cathodic protection stations. For convenience, the table shows stations of the same power, although many manufacturers can offer a whole range of manufactured stations.

SKZ - basic information.

Cathodic protection station (CPS)- this is a complex of structures designed for cathodic polarization of the gas pipeline by an external current.

Main structural elements VHC (Fig. 12.4.1.) are:

Ø source of direct (rectified) current (cathode station) 5 ;

Ø anode grounding 2 buried in the ground at some distance from the pipeline 1 ;

Ø connecting power lines 3 connecting the positive pole of the current source to the anode ground, and the negative pole to the pipeline;

Ø cathode outlet of gas pipeline 8 and drainage point 7 ;

Ø protective earth 4 .

Figure - 12.4.1. - Schematic diagram of the SKZ

The potential of the pipeline under the influence of the incoming current becomes more electronegative, the bare sections of the gas pipeline (in places where the insulation is damaged) become cathodically polarized and, depending on the magnitude of the established potential, becomes completely or partially protected from corrosion. At the same time, on the anodic grounding, under the action of the flowing current, the process of anodic polarization occurs, accompanied by a gradual destruction of the anodic grounding.

Sources direct current SCs are divided into two groups. The first group includes network converting devices - rectifiers powered by AC power lines (TL) industrial frequency 50 Hz with rated voltage from 0.23 to 10 kV. The second group includes autonomous sources - DC generators and electrochemical elements that generate electricity directly on the gas pipeline route near the place where it is necessary to install the CPS (wind power generators, electric generators driven by gas turbines, from the engine internal combustion, thermoelectric generators, accumulators).

On the main gas pipelines, network cathode stations with single-phase alternating current rectifiers with a voltage of 127/220 V, a frequency of 50 Hz are widely used. In the presence of AC power lines with a rated voltage of 0.23; 0.4; 6 and 10 kV, the use of such stations is expedient and economically justified. When powered from a 6 or 10 kV power line, the rectifier is connected to the supply line through a step-down transformer.

Figure - 12.4.2. – Simplified circuit diagram typical non-automatic power supply SKZ

On the fig.12.4.2. simplified typical scheme network cathode station with a rectifier. AC mains connected to terminals 1 and 2 . Accounting for consumed electricity is carried out by an electric meter 3 . Machine 4 serves to turn on the unit, and the fuses 5 provide current protection short circuit and overloads on the AC side. A step-down transformer 6 feeds the rectifier 7 , assembled from individual rectifier elements in a full-wave bridge rectification circuit or in a full-wave single-phase rectification circuit with a zero output. Protection against short circuit and overload on the side of the rectified current circuit is provided by a fuse 9 . The operating mode of the installation is controlled using an ammeter. 10 and voltmeter 12 . Connecting cable from pipeline 11 connected to the "-" terminal, and from the anode ground - to the "+" terminal. All elements of the installation are mounted in a metal cabinet, locked with a padlock.

To ensure safe operating conditions, all metal parts of the station structure are grounded with protective ground 8 .

Rectifier installations have devices for regulating voltage or current. In most installations, step voltage regulation is used by switching individual sections of the transformer windings. On some types of rectifiers, the voltage is continuously regulated using an autotransformer or magnetic shunts in the transformer windings. Triac voltage regulation is also used in the primary winding and thyristor - in the secondary.

In case of cathodic protection of gas pipelines located in the area of stray currents, the operating mode of non-automatic AC rectifiers is usually selected taking into account the average value of the potential difference "pipe - earth", which is determined from measurement data for a certain period of time (usually the average daily value) and does not exclude emissions potential into the anode or cathode region. To suppress anode surges, the rectifier must be set to the overprotection mode. Deep cathodic polarization leads to excessive consumption of electricity, peeling and cracking of the insulating coating, hydrogenation of the metal surface (due to intensive hydrogen release on the cathode). This nature of the change in the potentials of gas pipelines leads to the need to create automatic stations cathodic protection, which must maintain the potential in the protective range with a minimum consumption of electricity and maximum use protective properties wandering currents. SKZ consist of devices for setting the set value of the potential difference (driving devices), devices for measuring the actual potential difference (measuring devices with stationary reference electrodes), power amplifiers, executive bodies that change the current strength in the RMS circuit.

Electrochemical corrosion protection consists of cathodic and drainage protection. Cathodic protection of pipelines is carried out by two main methods: the use of metal anode protectors (galvanic cathodic method) and the use of external direct current sources, the minus of which is connected to the pipe, and the plus to anode grounding (electrical method).

Rice. 1. Working principle of cathodic protection

Galvanic sacrificial corrosion protection

The most obvious way to implement electrochemical protection of a metal structure in direct contact with the electrolytic environment is the galvanic protection method, which is based on the fact that different metals in the electrolyte have different electrode potentials. Thus, if you form a galvanic pair of two metals and place them in an electrolyte, then the metal with a more negative potential will become a protective anode and will be destroyed, protecting the metal with a less negative potential. Protectors essentially serve as portable sources of electricity.

Magnesium, aluminum and zinc are used as the main materials for the manufacture of protectors. From a comparison of the properties of magnesium, aluminum and zinc, it can be seen that of the considered elements, magnesium has the highest electromotive force. At the same time, one of the most important practical characteristics of protectors is the efficiency factor, which shows the proportion of the tread mass used to obtain useful electrical energy in the chain. K.P.D. protectors made of magnesium and magnesium alloys, rarely exceed 50% c, in contrast to Zn and Al-based protectors with efficiency. 90% or more.

Rice. 2. Examples of magnesium protectors

Typically, protective installations are used for cathodic protection of pipelines that do not have electrical contacts with adjacent extended communications, individual sections of pipelines, as well as tanks, steel protective casings (cartridges), underground tanks and tanks, steel supports and piles, and other concentrated objects.

At the same time, tread units are very sensitive to errors in their placement and configuration. Incorrect selection or placement of tread settings results in sharp decline their effectiveness.

Cathodic corrosion protection

The most common method of electrochemical protection against corrosion of underground metal structures is cathodic protection, carried out by cathodic polarization of the protected metal surface. In practice, this is implemented by connecting the protected pipeline to the negative pole of an external DC source, called a cathodic protection station. The positive pole of the source is connected by a cable to an external additional electrode made of metal, graphite or conductive rubber. This external electrode is placed in the same corrosive environment as the protected object, in the case of underground field pipelines, in the soil. Thus, a closed electrical circuit is formed: additional external electrode - soil electrolyte - pipeline - cathode cable - direct current source - anode cable. As part of this electrical circuit, the pipeline is the cathode, and an additional external electrode connected to the positive pole of the DC source becomes the anode. This electrode is called an anode ground. The negatively charged pole of the current source connected to the pipeline, in the presence of external anode grounding, cathodically polarizes the pipeline, while the potential of the anode and cathode sections is practically equalized.

Thus, the cathodic protection system consists of a protected structure, a direct current source (cathodic protection station), anode grounding, connecting anode and cathode lines, an electrically conductive medium (soil) surrounding them, as well as monitoring system elements - control and measuring points.

Drainage corrosion protection

Drainage protection of pipelines against corrosion by stray currents is carried out by directed removal of these currents to the source or to the ground. Installation of drainage protection can be of several types: earthen, straight, polarized and reinforced drainage.

Rice. 3. Drainage protection station

Earth drainage is carried out by grounding the pipelines with additional electrodes in the places of their anode zones, direct drainage - by creating an electrical jumper between the pipeline and the negative pole of the stray current source, for example, an electrified rail network railway. Polarized drainage, unlike direct drainage, has only one-sided conductivity, therefore, when a positive potential appears on the rails, the drainage is automatically turned off. In reinforced drainage, a current converter is additionally included in the circuit, which allows increasing the drainage current.