The history of moonshine shows that the production of alcohol products did not begin immediately in industrial scale: people began to get wine and moonshine at home, at first using artisanal methods. Nowadays, producing wonderful drinks has become much easier and safer - for this you just need (we recommend choosing a device with a distillation column of the brand or with a dry steamer of the brand). Subject to a series simple conditions driving moonshine correctly at home, as you can see, will not be difficult. How to drive moonshine in order to get a clean and pleasant drink at the exit? We'll talk about this below.

So for quality homemade moonshine Several factors are at play, namely:

- quality of raw materials for brewing mash

- water quality

- type and quality of yeast

- proper distillation and purification of moonshine

It may seem that all this is very difficult. Consider each criterion and it becomes clear that anyone can cope with the task of a distiller!

Point one. Braga

As you can see, the main share of the points responsible for quality belongs to Braga. A variety of products can serve as raw materials for mash. This is ordinary sugar, and cereals, jam, fruits, and even grape pomace. The latter, by the way, is used in the production of the famous chacha. To put the mash, you need four components: raw materials, water, sugar and yeast. However, with some raw materials it is even possible to do without the last two components.

The simplest mash is sugar. There are usually no surprises with her, so it is best to use her to get acquainted with the art of moonshine.

Ingredients for sugar mash:

- granulated sugar - 1 kilogram

- clean water - 5 liters

- pressed yeast - 100 grams

Cooking:

- Pour warm unboiled water (30 ° C) into the fermentation tank, add granulated sugar and stir until completely dissolved.

- Dilute the yeast according to the instructions, add to the water and mix thoroughly.

- We tightly close the container with a lid and install a water seal. In the old fashioned way, instead of a water seal, you can also use rubber glove with a hole at the end of the finger. Do not allow the mash to come into contact with air for a long time, otherwise acetic acid will form, and distillation will become impossible.

- We remove the container in a warm dark place with a constant temperature (24-28 ° C) for a week or two.

- How to understand that the mash is ready:

- gas ceased to be released (there are no bubbles in the water seal or the glove is blown off)

- Braga has a bitter taste, completely devoid of a sweetish aftertaste. If sweetness is present, the yeast has not processed all the sugar.

Usually, the finished mash is clarified (cleaned), for example, with bentonite (white clay). It can be purchased at an online store for home brewing goods, but you can do it easier. Bentonite is sold in stores in the form of ... cat litter. But carefully read the information on the package: bentonite must be pure, without flavorings. It is taken at the rate of one tablespoon (with a slide) per 10 liters of mash.

Braga lightening:

- Degas Braga (get rid of carbon dioxide). We heat the mash to 50 ° C and stir at this heat for 5 minutes.

- Pour 1-1.5 liters of warm mash into a saucepan and dilute bentonite in it.

- Pour the mash into a clarification container, add the bentonite solution and mix thoroughly.

- When the yeast with bentonite precipitated, the mash becomes transparent from cloudy.

- Carefully remove the mash from the sediment using a silicone tube. Now it can be overtaken.

Now let's talk about the quality of the water used. Pure spring, spring water is best for mash. The softer the water, the softer the moonshine will be. Tap chlorinated water is better to stand for a couple of days before use, so that the chlorine disappears. boiled water cannot be used due to the lack of oxygen in it, which is necessary for yeast in the process of life.

And what about yeast? For those who wondered “how to drive moonshine correctly”, the question “how to choose the right yeast” is of paramount importance.

- Baker's yeast is available and cheap, but produces less alcohol and is "coarse". However, they are still actively used for making mash.

- Brewer's yeast is specific and gives a low yield of alcohol. Plus they form a lot of foam. Spirit yeast is the best choice, as it gives a good strength of the mash (and hence the alcohol yield) and significantly increases the fermentation rate compared to baker's yeast.

- Wine (or wild) yeast lives on grapes. They are used in the preparation of grape mash.

Now let's talk about the distillation process, namely, how to drive moonshine through a moonshine still from a properly prepared and ripened mash.

Why the moonshine still, and not? Because these “old-fashioned” methods are used in extreme, and not at home, conditions, and they produce moonshine of such poor quality that the skin is not worth the candle. Of course, if you want to enjoy a drink, and not warm up in the conditions of the far north.

Point two. We distill moonshine

Distillation can be non-fractional and fractional (with separation of head-body-tails fractions). Of course, you can immediately be puzzled by fractional distillation, but it’s better to do it easier and first drive out all the alcohol to the maximum. And only then the resulting raw alcohol is distilled again with the separation of fractions. So we get a better pure product.

- Pour the mash into the distillation cube and set the maximum heat.

- We will still take the first drops, they are too poisonous. For every kilogram of sugar used in mash, 30 ml of “heads” must be selected. You can use “heads” on the farm, but in no case should you drink.

- We change the receiving container and drive out the moonshine until its strength drops to 20-15 degrees. We have received a “body”, this will be our raw alcohol. Its strength will be approximately 50 degrees.

- Then we drive out the “tails” until the fortress falls almost to zero. They can later be used to strengthen the mash.

Between the first and second distillation, raw alcohol can be purified with charcoal, milk or butter.

The second distillation, or how to drive the second moonshine.

- Raw alcohol is diluted to a fortress of about 20 degrees and poured into a cube.

- Set the maximum heat.

- As soon as the first drop has fallen from the refrigerator, we reduce the heating so that the moonshine comes out at 1-2 drops per second.

- At the indicated speed, we select “heads” (approximately 50 ml per kilogram of sugar used in the mash). When selecting heads, we are guided by organoleptics: as soon as the smell of the liquid ceased to be unpleasant and became pure alcohol, we change the receiving container).

- The selection of the body is carried out to a fortress of 45-40 degrees in a stream, as thick as a match, as far as heating and a refrigerator allow. The strength is measured with a household alcohol meter at an air temperature of about 20 ° C. However, the temperature of the alcohol at the outlet of the refrigerator may differ from 20 ° C, so the alcohol content value may be slightly distorted.

- After selecting the body, we select the “tails” at maximum heating to a strength of 10 degrees or a little lower.

The moonshine obtained after the second distillation is in the highest degree clean and high quality. It can be consumed as an independent drink or used in.

How to properly drive moonshine with a steamer, if it is in the design of the apparatus?

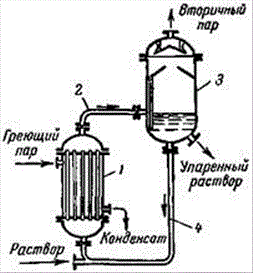

The distillation technology in this case remains the same. But if available given element the system increases the degree of purification and, as a result, the quality of the resulting moonshine. Sukhoparnik is designed to separate fusel oils from vapors ethyl alcohol. This airtight container with a size of no more than a tenth of the volume of the cube must be collapsible. The dry steamer is located between the distillation cube and the coil. Sukhoparnik can be used for both primary and secondary distillation. Hot vapors of alcohol containing fusel oils are slightly cooled when they enter the sukhoparnik. Fusel oils settle on the walls, and then new portion hot vapor heats up and carries away ethyl alcohol and other low-boiling fractions, and fusel oils remain in the steamer. In addition, the sukhoparnik protects the system from splashing - ingress of mash drops.

Distilling moonshine is not so easy? is a process that requires certain knowledge, skills and equipment. Well-made moonshine is not a shame to treat guests, you can make good wine drinks from it, which will serve as decoration holiday table. But this is possible only if the moonshine is properly distilled, and the alcohol contained in it will not have foreign impurities.

Technology of primary distillation of mash into moonshine

The primary distillation of mash into moonshine can be done in several simple ways.

Freezing

This method allows you to isolate alcohol from mash without distillation apparatus. This will require a container and a negative temperature. Water freezes at a temperature of 0 ° C, alcohol at more than - 110 0 ° C. When using this method, the mash separated from the sediment is poured into an enameled bucket and taken out into the cold, while the air temperature should not be lower than 10 ° C. The lower the temperature air, the faster the process of extracting alcohol from the mash. After about 6-8 hours, a loose ice mass forms in the bucket, between the pores of which there is an alcohol-containing liquid, which is poured into a separate container.

In the second method of freezing, a metal chute is used, which is installed at a slight slope. The longer the chute, the more alcohol will be in the resulting product. This technology is very simple, a thin stream of mash is poured onto the upper end of the gutter, and the resulting moonshine is poured into the container substituted under the lower end. Flowing down the gutter, the water freezes to it, so the slope should not be very steep. The air temperature during this process should be at least minus 25? 30 O S.

Evaporation

A stand is installed in a large saucepan and the mash is poured. The level of the mash should not be higher than the level of the stand on which  a container for collecting moonshine is installed. This capacity should be at least half the diameter of a large saucepan. A wet towel is placed on the edges of a large saucepan and a basin with cold water. The structure is placed on a stove and heated to a temperature of 60? 70 ° C. The water in the basin is changed as it warms up. After 50-60 minutes, the resulting moonshine is drained from the collection container.

a container for collecting moonshine is installed. This capacity should be at least half the diameter of a large saucepan. A wet towel is placed on the edges of a large saucepan and a basin with cold water. The structure is placed on a stove and heated to a temperature of 60? 70 ° C. The water in the basin is changed as it warms up. After 50-60 minutes, the resulting moonshine is drained from the collection container.

Alcohol-containing liquid, which is obtained by such methods, contains a large number of aldehydes, methanol, fusel oils and other harmful substances. Therefore, it is simply not possible to use the resulting liquid without a shudder, it causes a very strong hangover syndrome and among the people it received many biting names reflecting its essence, one of which? ?shmurdyak?. It will not be possible to completely clean it of the remaining impurities, and tinctures and liqueurs made on its basis will have a characteristic smell and give off fuselage.

Distillation with moonshine

A better product is obtained if the mash is distilled using a moonshine still based on a distillation cube and a coil, which is a tube twisted into a spiral. A good distillation apparatus should be made of materials that do not react with the resulting products. It's best if it's made from  of stainless steel or food grade aluminium. Modern factory-made moonshine stills have in their design dry steamers for separating heads (aldehydes, methanol, ethers) and thermometers to maintain the required temperature in the distillation cube. Such designs are quite expensive, but if desired, they can be made independently.

of stainless steel or food grade aluminium. Modern factory-made moonshine stills have in their design dry steamers for separating heads (aldehydes, methanol, ethers) and thermometers to maintain the required temperature in the distillation cube. Such designs are quite expensive, but if desired, they can be made independently.

The technology for distilling mash into an alcohol-containing liquid is as follows. Is clarified or settled mash not more than poured into the distillation cube? container volume. The liquid is heated over low heat to a temperature of 65-75 ° C. At this temperature, fractions with a low boiling point evaporate, which should be separated from the main body containing alcohol. It is quite simple to determine the number of heads to be cut off: 1% of the filled mash or 5% of the resulting product. It is also simple to determine the amount of moonshine received - how many kilograms of sugar were poured into the mash, how much approximately will it turn out to be 60? 65% moonshine. After cutting off the tails, the mash is heated to a temperature of 80-90 ° C and the liquid is taken until its strength drops to 40%. In the further part of the output product, along with alcohol, there will be a large amount of fusel oils, the use of which is harmful to health.

Improving moonshine by re-distillation

Is the resulting moonshine subjected to cleaning? chemical or biologically by adding manganese, activated charcoal or egg white. Despite the cleaning carried out in moonshine back in  impurities will be contained in sufficient quantities, the removal of which will require repeated distillation of the resulting product. If moonshine is distilled twice, then the alcohol content in it increases significantly and the level of harmful substances decreases. Therefore, to get quality products based on moonshine, its secondary distillation will be required.

impurities will be contained in sufficient quantities, the removal of which will require repeated distillation of the resulting product. If moonshine is distilled twice, then the alcohol content in it increases significantly and the level of harmful substances decreases. Therefore, to get quality products based on moonshine, its secondary distillation will be required.

Repeated distillation makes it possible to almost completely eliminate the content of aldehydes, methyl alcohol, esters and similar harmful substances in the product. The content of fusel oils also decreases many times and gives the resulting product a light specific smell and taste that does not have a significant impact on health. It is possible to re-distill the tails, this will greatly increase the amount of alcohol obtained during fermentation. Therefore, despite the increase in time to obtain a properly made product, re-distillation of moonshine is highly desirable.

How to re-distill

Re-distillation of moonshine is carried out using a distillation tank and a coil, freezing and evaporating the resulting product will not improve its quality. Before re-distillation, moonshine is cleaned from existing impurities. Calcium permanganate (potassium permanganate) sold in a pharmacy is best suited for this. To clean 3 liters of moonshine, add a solution of 3 grams of potassium permanganate in  300 g of water, mixed and allowed to stand for 1-2 hours. After that, the alcohol-containing liquid is separated from the precipitate using a siphon tube, paper or carbon filter.

300 g of water, mixed and allowed to stand for 1-2 hours. After that, the alcohol-containing liquid is separated from the precipitate using a siphon tube, paper or carbon filter.

Before the second distillation, moonshine is diluted with clean cold water to a strength of 20? 25%. This is necessary to ensure the safety of the apparatus, from possible ignition of liquid vapors. Also, dilution with water will destroy the strong molecular bonds of fusel oils and alcohol. For best quality solution, you can use distilled water, which can be purchased at any automotive store. Is the strength of the solution checked with an alcohol meter or, in extreme cases, with a strip of moistened paper? it shouldn't burn.

The process of double distillation is the same as primary distillation, but has its own characteristics. The boiling point of ethyl alcohol is 79 o C, but at this temperature the process will be very long. Therefore, it is better to distill the liquid twice at a temperature of 85-90 ° C. For exact definition temperature, you will need a thermometer built into the distillation cube. Keep the temperature down

also does not follow, in this case the process will be delayed and water vapor will enter the product in large quantities.

The first 2-8% of the filled volume are heads, which are cut off. The percentage of separation of heads depends on the method of obtaining moonshine. If at the initial stage a distillation apparatus was used, and the heads were removed, then this percentage will be minimal. If freezing or evaporation was used, then the volume of heads will be large.

The next part is the body. They stop taking it when the strength of the outgoing product drops to 45%. An alcohol meter should be used for measurements. Next will be the tails, which can be used for the next portion of the distilled mash. The twice distilled product has a strength of 65-70%, and by diluting it, you can get various alcoholic products. For the final improvement of moonshine, it can be finally cleaned with egg white, which, folding, absorbs the remaining additives.

Redistillation errors

The main mistake of re-distillation is the violation temperature regime. At high temperatures, the process is accelerated, but at the same time, in addition to ethyl alcohol, the content of fusel oils in the moonshine increases. Low temperature reduces the amount

outgoing alcohol. The next common mistake is to heat coolant coil. When tested for combustion, warm alcohol vapors ignite easily, misleading the manufacturer.

On the Internet, you can find the opinion that when re-distilling, moonshine should not be diluted with water, as it deteriorates. taste qualities. This is a rather controversial opinion. The smell and taste are mainly influenced by fermentation products, which are separated during the distillation process. But the distillation of an undiluted product in the case of farce majeure circumstances can lead to unpredictable consequences. Savings in the removal of heads and tails will also significantly affect the quality of properly made moonshine.

The choice is yours.

I will not describe the mode of distillation, because. for each design it has its own, I will only describe general principle, which is suitable even for the simplest moonshine still, made, for example, from a milk can or a beer keg and a bucket with a copper coil.

The purpose of the first distillation is to separate the alcohol from the insoluble impurities of the mash. In my opinion, moonshine cannot be drunk after a single distillation of sugar brew, it was not entirely accurate to drink it, but it is not tasty, especially after you try at least once moonshine that has been distilled more than once and has undergone additional purification. But already the moonshine that you will receive after the first distillation, taking into account the above recommendations, will differ from ordinary moonshine for the better.

It is usually recommended that the first distillation be carried out at maximum power, as quickly as possible from start to finish, without dividing into fractions. Such recommendations are due to the fact that yeast should be boiled as little as possible, because this worsens the quality of the product, both in terms of impurities and organoleptics, and subsequent distillations are recommended to be carried out fractionally, dividing into the head fraction, body (drinking part of the distillate) and tail fraction. Undoubtedly, such an opinion is by no means erroneous, but I recommend that you carry out crushing / separation into fractions already in the first distillation.

In order to more clearly separate the head fraction, saturated with harmful impurities, boiling at a temperature lower than ethyl alcohol, distillation is carried out at a lower speed, which contributes to less evaporation of ethanol with a greater evaporation of head fractions. But even at a higher distillation speed, head impurities will be separated first of all, because the boiling point of the mash does not depend on the selected power for heating the distillation cube, but depends only on the percentage of alcohol in the distilled mash. Each % has its own temperature (to determine this you can use, kindly made by your colleagues), but for a start we will not focus on any temperature data, because it is quite possible that your distillation apparatus is not equipped with a thermometer.

At the first distillation, I recommend that you collect 30 milliliters of distillate from each kilogram of sugar in a separate container, that is, if we poured a total of 5 kilograms into the mash, then we will take the first 150 grams into a separate bowl and put them aside, you should not use them, but also pour it out, later I’ll tell you how you can use them.

After we have selected the head fraction and replaced the receiving container, we begin the selection of the so-called body, again I recommend that during the first distillation, fractionally select the body not only from the head fraction, but also from the tail, because and it will contain a large amount of fusel impurities and will spoil the taste of the product. In milliliters, in this case I can’t give advice, but at the first distillation, I’ll advise you to change the receiving container until the alcohol content at the distillate outlet reaches 40%, the fortress is best measured with a hydrometer (alcohol meter), at a temperature of 20 ° C, dialing directly from the refrigerator into the flask the necessary quantity to measure. If, for some reason, you do not have this device, then until the distillate burns in a spoon, at the same 20 ° C. If you set fire to paper or if the liquid is much warmer, then it will burn with a lower concentration of alcohol. After changing the receiving tank, we select the tail fraction until the complete absence of alcohol. As drinking, we will not use it, but just like the head fraction, the tail fraction should not be poured out, because after additional purifications we will get a certain and not very small amount of ethyl alcohol from them.

After separation into fractions, we will use the body (middle fraction) as a raw material for obtaining sugar distillate of double or triple distillation, because. for us it's just raw alcohol (SS). It is possible and necessary to subject the secondary distillation to separation into fractions in order to further remove head and tail impurities, but before that, I recommend doing the so-called intermediate purification.

I will describe to you two, in my opinion, well-established and personally proven by me methods of intermediate (between fractional distillations) purification.

Both of these methods can be used independently and separately from each other, but more nice results you can get by using both methods in turn, because they only complement each other.

As the first method, consider oil cleaning, as the second - activated carbon cleaning. Oil cleaning is carried out first, not because the method is more effective or better than the second, simply, if you use both methods, then they must be carried out in that order.

cleaning activated carbon is based on the adsorption ability to selectively absorb / absorb some impurities from raw alcohol due to the developed surface of the coal, as well as its catalytic ability to convert one component into another.

The same qualities are possessed by the ordinary charcoal, but activated due to a more developed pore surface, it is 5 times more effective and there will be no resin residues in it that can pass from poor-quality burned coal into a distillate. It is recommended to use crushed 1-3 mm birch activated carbon (BAU-A) or stone fruit/coconut activated carbon (KAU) for cleaning raw alcohol.

In my opinion, the flow-through method of purification through a column - a filter filled with activated carbon has proven itself better. It has also been noticed that the lower the strength of the liquid being purified, the more efficiently impurities are absorbed from it; your raw material is already diluted and additional dilution is not required.

It has been proven that activated carbon can absorb 90% of esters and up to 80% of fusel oils from a water-alcohol mixture.

There are many ways and possibilities to pass liquid through a layer of coal, for example using forced air pressure or vacuum suction. But for starters, you can use improvised materials and make a flow filter.

Such a filter can be made from the usual plastic bottle from under mineral water, cutting off the bottom of the bottle, making several holes in the cork with an awl, inserting a cotton pad at the cork, filling it with coal, and placing it on a regular 3 liter jar. Such an impromptu filter can be made in 2-3 minutes, but if you are going to use this method often, then it is better to make the device more practical and aesthetic. Everyone can choose the amount of coal for filtration, but I recommend about 5-15 grams per liter of filtered liquid. Before falling asleep in the filter, it is advisable to wash the coal from coal dust, because. it can clog the cotton filter and without additional pressure, the cleaning speed will tend to zero.

Cleaning with oil and activated carbon is also applicable and gives good results with distillates from starchy raw materials. For distillates from fruit and berry raw materials, intermediate purification is not recommended, but will be limited to only two or three fractional distillations.

If you add 20 g of dark raisins for each filled liter of diluted raw alcohol before the second distillation, then the taste and smell of your drink will be such that many gourmets will not be able to determine that it is made from ordinary sugar, water and yeast.

Well, we have made two intermediate purifications and now it is time to carry out the second fractional distillation, so that the distillate acquires a fortress and, most importantly, to get rid of the head fractions and, as far as possible, from the tail fractions that still remain after our previous purifications.

The principle of fractional distillation itself is not much different from how we distilled it for the first time, but there are some nuances. We select the head fraction slowly, after the appearance of the first drops of distillate from the refrigerator, we reduce the power so that the distillate drips at a rate of approximately 2-3 drops per second. At this speed, we select 50 milliliters from each fermented kilogram of sugar. After that, we change the receiving container and begin the selection of the body (drinking fraction). The selection is carried out at medium speed, the selection of the body continues until the fortress at 20 ° C becomes 45%. We change the receiving tank for the addition of the tail fraction, because. there is still a lot of ethyl alcohol left. The tail fraction after the intermediate cleanings with oil and AC will no longer smell so clearly of fusel oil, but, nevertheless, it is not recommended to interfere with the body.

Depending on the design of your apparatus, after the second distillation, you will receive about 400 g of 50-60% distillate with a kg of sugar, only vaguely resembling the moonshine that you once sniffed.

Since high is not acceptable for everyone, the body after the second distillation can be diluted with water.

should be soft and not contain many minerals, you can use reverse osmosis water, bottled purchased water, with a mineral content of not more than 1 mg / l. You can also prepare water at home by purifying it through an ordinary household filter - a jug, then boil for 10 minutes and let it stand for a day. After settling, sediment will appear at the bottom, then this water can be passed through the filter jug again, after which it can be used to dilute the distillate. I do not recommend diluting below 38%. Do not forget - the fortress will be determined by a spirometer at 20 ° C!

You can also use special calculators.

After distillation and dilution, it is recommended to keep the distillate in bottles for a couple of days, let it rest, after which the drink becomes softer and more balanced. You can also pour the distillate into a saucepan and heat it without a lid until the first visible signs evaporation of the distillate, and then let it cool without a lid in the same saucepan and pour into bottles that have already cooled down. Thus, we will still soften the taste of the drink and make it more rounded, but we need to expect that in this way we will lose 1-2% of alcohol.

A little about the processing of head and tail fractions.

Having accumulated a sufficient amount of these fractions, you can clean the tail fractions with oil, as described above, and dilute the head fraction, pass it through a carbon filter and then mix these, if I may say so, waste, fractionally distill together.

The quality of such a distillate will not be high, but nevertheless it can be consumed, especially if it is previously kept in contact with or oak bark along with. In any case, this distillate will be an order of magnitude higher quality than regular sugar moonshine.

So, we have a transparent drink in the bottle, which we made at home and which we can proudly call a sugar distillate, which is not a shame to put on the table in front of the guests or come to visit with such a drink, and the skeptics, having tried what you treated them to, turn into fans of the results of your hobby.

Delicious and healthy drinks!!!