The basement is one of the most important parts of the building. This is a kind of support, which is subjected to constant negative influence environment. Finishing the basement of a private house not only gives it an aesthetic appearance, but also protects it from adverse factors. Therefore, finishing materials must be moisture-resistant, frost-resistant, reliable and durable.

Much of the building's foundation is below ground level and hidden from view. The protruding part above ground level is called the plinth. According to the norms, the height of the basement from the ground must be at least 20 cm. It is usually made of brick, stone or concrete slabs.

The construction of a stone plinth is the most practical solution, since the structure does not need additional finishing. However, it is worth considering that this is the most costly way. Brick plinth masonry is more affordable. This material environmentally friendly, has a low and good performance strength.

Facing the basement of the house is not only aesthetic. This is a reliable protection of the building from external influences. Finishing materials that will be used for sheathing the basement must have a high level of strength. Together with the plinth, its cladding will take the load created by the wall structures of the building and evenly distribute it over the foundation of the building. It must withstand pressure and protect the base from external factors such as precipitation, sunlight, humidity, temperature fluctuations.

Finishing material protects the foundation of the building from damage by mold, fungus and various types insects. The lining of the basement is carried out in order to insulate the building. It is also necessary to protect the foundation from severe frosts, under the influence of which its strength decreases and the erosion process develops.

Leaving the surface of the plinth without sheathing will contribute to its slow destruction as a result of constant exposure to dry or liquid dirt containing aggressive chemicals and minerals.

Various options for finishing the basement of a private house, the photos clearly confirm this, turn the building into a masterpiece of design art, making it look complete and unique.

Varieties of basement structures

There are main variations of structures that are used for projects of houses with a plinth:

- protruding beyond the surface of the walls;

- flush with the building;

- sinking, relative to the wall.

Most often, when building a private house, a photo of the basement of the house clearly confirms this, using the first two options. A protruding plinth is recommended when a house is being built with thin exterior walls, a warm underground is used, or the building provides basement. In these cases, this type of plinth will provide the building with additional thermal insulation.

If the basement is made flush with the building, when thin walls are used for its construction, dampness and condensation in the interior are inevitable. Here it is most problematic to mount thermal insulation and perform finishing.

Important! When choosing these types of plinth, you should take care of the arrangement of low tides in advance.

The sinking base is less damaged by the influence of precipitation. Here you can easily hide the waterproofing, equip the insulation and complete the cladding with the necessary materials, which contributes to a longer service life. This type of plinth is recommended for buildings without a basement. Finishing materials for the plinth will perceive the pressure of the soil, performing a supporting function, thereby maintaining the safety of the entire structure.

The procedure for finishing the basement of the house

All work on the lining of the basement structure is carried out at the final stage of production - the exterior of the building. Work is best done in warm, dry weather. The basement sheathing consists of the following steps, which are performed in a certain sequence:

- A trench is dug 20 cm deep, 50 cm wide around the entire perimeter of the building.

- Filling the space with gravel to provide drainage. Additionally, the trench can be strengthened using a reinforcing mesh.

- The surface of the wall, 50-70 cm high for the future plinth, is cleaned of dirt and processed. If necessary, all irregularities are eliminated.

- Arrangement of thermal insulation.

- Decorative lining of the plinth.

The choice of facing material and the way it is laid depends on the design of the plinth and the method of its outflow.

Arrangement of low tides for the basement of the foundation

To protect the basement from the negative effects of precipitation, an ebb should be installed, which is fixed above the protruding part of the basement, and is a kind of delimiter between the base of the building and the wall structure. One part is in contact with the wall at a certain angle, and the other hangs over the foundation, blocking it, collecting rain and melt water.

Ebb for the plinth are slats with a size of 50-400 mm. The color, size and shape of the tides should be selected depending on the finishing material of the foundation. A water-repellent structure can be made independently using waterproof materials, or you can buy ebbs for the basement of the foundation in ready-made at any hardware store.

Today, the industry produces several varieties of ebbs:

- plastic;

- metal;

- concrete;

- clinker.

The type of tide is selected based on the finishing material for the facade of the building. The most successful plastic ebbs are combined with vinyl siding, which is used for building cladding. Due to the wide range of colors, you can choose the most suitable option. The use of concrete or clinker flashings for the plinth is preferable for buildings that are lined with natural stone or brick. Metal visors can be used with any kind of finishing material.

Varieties of ebbs

by the most budget option is the use of plastic moldings made of polyvinyl chloride. The cost of the product is 50 rubles. for 1 running meter Despite the high rate of water resistance, ebbs show hypersensitivity physical impact, especially winter period when from the slightest blow they can crack and split.

Useful advice! Due to the fact that plastic ebbs have increased fragility, preference should be given to more durable and expensive products.

The most durable and durable are ebbs made of metal: steel, copper or aluminum. Installation of products is convenient and simple, and is determined by fastening metal strips to the walls of the building using self-tapping screws and dowels. Choosing this material from a wide range of species, you should special meaning pay attention to the aesthetic appearance of the product, so that it creates the completeness of the overall design of the building. The price of the product starts from 100 rubles/p.m.

Useful advice! When mounting the base sills, the strips should be overlapped one after another by at least 30 mm. To avoid damage to the protective layer of the product, which will lead to the formation of corrosion and destruction of the material, do not cut the planks.

Metal castings are made from high-quality and frost-resistant cement of the M450 brand with the addition of river sand, crushed granite and plasticizers. The solution is poured into silicone molds of various geometric parameters. The result is a flat and smooth product. These ebbs are attached to a special solution.

Ebb for the basement of the foundation, the price of which is the highest and starts from 200 rubles. for 1 running meter, these are products made of clinker tiles. This material has high strength characteristics, reliably protects the building from the negative effects of the environment and successfully emphasizes the design of the cladding.

Drain mounting technology

After choosing the ebb, you can proceed to its installation. Here, one should take into account not only the material from which the ebbs are made, but also the design features of the building. Yes, for wooden house suitable elements that will be fastened with self-tapping screws or other fasteners. Since wood has low adhesion and is afraid of dampness, the use of adhesives is impractical.

For buildings made of brick or facing stone, ebbs can be used, which will be attached using polymer or cement-adhesive mortars.

Useful advice! When using concrete or ceramic sills, their installation should be carried out simultaneously with the plinth and wall cladding.

If it is necessary to install ebbs on a building already finished with facing material, then it is better to use metal or vinyl elements.

Before installing the ebbs, it is necessary to seal the joints of the walls with the plinth. All cracks and crevices should be treated with a water-repellent mixture, or sealed with a sealant. Next, you need to use the level to mark the wall. The most high point plinth and a horizontal line is drawn along which the upper part of the tide will be mounted. The part of the foundation that protrudes must be compared with a horizontal plane using a cement screed. The lower part of the tide will rest on it.

Important! The ebb plane relative to the wall should be located with a slope of 10-15%.

Installation of metal and plastic sills

The installation of sills should be started from the corner, using special corner elements that can be purchased together with planks of the same width and color. Next, you need to finish all the protruding parts of the building structure: columns, pilasters and others.

Related article:

What materials are used for castings. Which of them is better to choose and in which case. Drainage installation.

In the upper part of the tide, holes are drilled with a drill at a distance of 40-50 cm from each other. Further, the element is applied to the previously outlined line on the wall of the house and is attached to it with dowels with self-tapping screws. Bottom part ebb with the help of dowel-nails is attached to the concrete base of the plinth in increments of 40-50 cm. The joint of the ebb with the wall should be sealed with putty or silicone compound.

Important! During the installation of the ebb, it should be borne in mind that it should protrude 2-3 cm beyond the edge of the base, which will ensure better protection during precipitation.

After sheathing all corners and protruding elements, it is necessary to proceed with the installation of ebbs on straight sections. You need to start from one of the corners. Each next element should be overlapped on the previous one by at least 3 cm. All joints should be treated with a sealant to prevent moisture ingress.

Installation of concrete and clinker sills

Clinker and concrete sills should be mounted at the stage of facing the facade of the building, since their adjustment to size during installation is a laborious process.

These types of ebbs are better combined with facing materials such as brick, clinker tiles, natural or. For their fastening, a special adhesive composition for ceramics and stone, which is intended for outdoor use, should be used. It is purchased in the form of a dry mixture created on a cement or polymer basis, and with the help of water it is brought to the state of thick sour cream. The solution can be made independently, using cement and building sand in a ratio of 1:3 or 1:4.

Installation of concrete and clinker sills also starts from the corner. In order to avoid difficult processing of concrete sills, they should be pre-positioned in such a way as to minimize their cutting. This can be achieved by using the right size of the seam between the elements. You can adjust the dimensions of clinker products by using a tile cutter or a grinder with a diamond cutting wheel.

An adhesive mixture is applied to the back of each element. The tide is fixed strictly along the previously outlined line. After waiting some time for the solution to set, putty or silicone sealant is applied to the joints between the casting elements. After the adhesive has completely set, the walls of the building can be clad.

Foundation plinth waterproofing

The basement of the building is constantly in difficult conditions. It perceives a significant load from the above-ground part of the building and is in contact with the external environment, being under the influence of moisture. In order to protect an important part of the house from destruction, it is necessary to provide for a number of measures, one of which is the arrangement of waterproofing of the basement of the foundation.

Waterproofing can be horizontal and vertical. Usually a complex of works is performed, which includes both methods. Horizontal waterproofing is performed before the walls are erected and is aimed at protecting them from moisture. However, in order to provide a complete protective package of measures, it is also necessary to perform waterproofing between the foundation and the plinth.

Vertical waterproof protection is aimed at preventing the negative impact of surface and ground water on brick or concrete. Such isolation can be external and internal. best effect has double-sided protection against moisture.

Today, pile foundations are predominantly used in the construction of buildings. Here the plinth plays not only a decorative role, but also protects the house from heat loss. Despite the fact that this element is not load-bearing and does not have a direct impact on the durability of the structure, waterproofing the basement is mandatory.

Materials for waterproofing the plinth from the outside

Coating, roll and injection compounds with a penetrating effect are widely used as materials that are used for waterproofing the basement of the foundation.

To protect the foundation from the effects of groundwater, rolled waterproofing is often used, which can be welded or pasted over. Fused insulation consists of a base in the form of fiberglass, polyester or fiberglass and applied mastic. Pasting waterproofing is laid on the surface of the foundation using bituminous mastic, which is first applied to the rolled material and to the monolith, then the element is glued, pressed and smoothed.

The main advantage of the roll material for the base plate is its low cost and high installation speed. However, this type of waterproofing is poorly resistant to mechanical stress and has a short service life. It cannot be used in places of passage or junction of communications. Before installation, clean the surface from dust and dirt, and dry thoroughly.

Bitumen, polymer, bitumen-polymer mastics, binder plasters and cement coatings are used as coating waterproofing materials, which are applied to the foundation surface with a brush or roller. This type of insulation is used for water pressure up to 2.6 kgf/cm².

Useful advice! To ensure increased strength of waterproofing after the first layer of mastic, it is recommended to reinforce the surface with fiberglass, and apply subsequent layers on top of it.

The material has a low cost and can be applied to the surface of any configuration. However, it is not durable, requires preparatory work and creation additional protection from mechanical impact.

The use of injection and penetrating compounds is the latest technology for waterproofing a structure. The penetrating material is applied to the damp surface of the concrete base. Reacting with water, the composition turns into crystals that penetrate into the pores of the concrete, making it waterproof. The penetration depth reaches 150-250 mm.

Injection waterproofing is carried out using a liquid solution, which is injected under pressure into the cracks, pores and seams of the structure. This method can be used for waterproofing a building made of rubble and brick. The use of this waterproofing is a very time-consuming process that requires cleaning the structure to concrete or brick, and the complexity of the work itself requires the involvement experienced craftsman. In addition, such isolation is the most expensive.

Features of waterproofing a brick basement

Ceramic brick is most often used for the construction of a basement. The device of its waterproofing can be carried out by various methods.

For the construction of walls, solid red brick can be used. This building material has already been factory processed, where a layer of waterproofing was previously applied to it. Therefore, using this brick for the construction of a building, external waterproofing can not be equipped. Despite the fact that the cost of this material is relatively high, these costs are offset by the fact that after laying the brick, no other work is required.

The next way to waterproof a brick basement is to use bituminous grease, which is applied in several layers in cold or hot form.

Rarely, polyurethane foam spraying is used to insulate the basement. This is due to the fact that in order to perform such a thermal protection option, it is necessary to use special equipment, certain chemical components and attract highly qualified workers. The essence of the method is that the foamed polyurethane foam is sprayed onto any surface. Expanding, it penetrates into all voids and securely adheres to the base, forming a dense coating. This material can be used not only for spraying, but also for filling individual voids and areas.

Do-it-yourself technology for insulating the basement of the foundation from the outside with foam plastic

At the preparatory stage, it is necessary to prepare the foundation surface by cleaning it of old insulation, dirt and dust. Next, you should equip a layer of waterproofing to protect the structure from rain, ground and snow water. Any type of waterproofing is suitable for penoplex, with the exception of compounds with organic components.

Work begins with the insulation of the underground part of the foundation. For this purpose, PPS boards are attached using a specialized contact adhesive, which is applied around the perimeter of the product and in the center. The second level should be laid with a gap between the joints between the plates in relation to the lower level. After installation, all slots are filled with mounting foam.

The basement insulation layer with foam plastic requires additional protection against mechanical damage. To do this, an alkali-resistant reinforcing mesh is fixed on the plates, which is subsequently plastered with a solution with hydrophobic additives. Also, as protection, you can use wooden tongs, which are attached to the plates with dowel-nails. Wood must first be subjected to antiseptic, antifoam and hydrophobic treatment.

The final stage is the finishing of the plinth with facing materials.

Facing the basement of the house: what material is better to choose

Do-it-yourself plinth finishing is carried out with various materials that reliably protect and decorate its surface. This process must be carried out before wall cladding in order to be able to hide the ebbs under the wall finishing material.

The plinth cladding material must have the following performance characteristics:

- have low thermal conductivity to avoid heat loss from the building;

- provide reliable and strong adhesion to the base;

- have a high indicator of strength and wear resistance to mechanical damage;

- have low hygroscopicity and vapor permeability to prevent moisture penetration into the foundation and wall panels.

Today, when the question is raised, how to finish the basement of a house, the following materials are used that fully meet the above requirements:

- clinker or porcelain tiles;

- natural or artificial stone;

- brick;

- PVC panels or basement siding;

- profiled sheet;

- decorative or mosaic plaster.

For lining the base of the strip foundation, you can use any finishing material. But when the question arises, how to close the basement of a house on screw piles, you should give preference to brickwork, siding or profiled sheet.

Before deciding how to finish the basement of the house from the outside, it is necessary to take into account some of the nuances:

- lining the base with thick material, it is necessary to install a low tide above its protruding part;

- wanting to expand the foundation, it is better to use brickwork;

- when mounting or corrugated board, you must first install a frame, the space of which can be filled with a heat insulator for additional insulation of the foundation;

- frame-facing technology allows you to carry out work at any time of the year.

Using plaster for plinth cladding

When the question is: how to inexpensively finish the basement of a house, the answer is obvious - use plaster. However, this option is the least durable, and also has an unaesthetic appearance. Such a lining is easily damaged by any mechanical influences and does not provide adequate protection of the base from external factors. However, this method is widely used due to its low cost. It is also acceptable in the case of building a brick base on a strip foundation.

Plastering itself is not the final stage. To protect the layer from moisture and environmental influences, it should be applied with acrylic, alkyd, silicone paint, water-based or oil composition, which in turn decorates the plinth. The photo of finishing the house clearly demonstrates the various options for using plaster.

Useful advice! Enamel paints are not recommended for painting the plinth. They do not pass air and are environmentally unsafe.

Often, decorative plaster is used, which creates the effect of a fur coat and can be colored when using a dye. The use of mosaic plaster allows you to create a multi-colored mosaic on the surface, which is due to the presence of small crumbs in the initial mixture. The presence of resin, as a binder, gives the composition increased water resistance.

To solve the question of how to make a plinth around the house with your own hands with the effect of natural stone, the use of a special silicone stamp will help, with which prints are made on the plastered surface.

In private houses, the basement finish with a profiled sheet is widely used. The material has a high moisture resistance, is resistant to temperature fluctuations, is durable, easy to process and can be easily mounted on a wooden crate. However, corrugated board is not suitable as a finishing material for wooden buildings due to the fact that it is susceptible to corrosion under the influence of high humidity, which can lead to rotting of wood.

Profiled sheets are often used to finish the plinth of a pile-screw foundation, where it must be closed for reliable protection from atmospheric influences.

Features of using brick for finishing the basement

One of the expensive finishing materials is brick. However, having high strength and performance characteristics, it allows you to create a strong, reliable and durable protection. This material is suitable for any type of foundation. For brickwork, slotted, hollow, hyperpressed or ceramic bricks should be used. Work begins with the arrangement of the base for masonry.

If the brick is used to build the basement itself, it does not need additional finishing. However, here you should choose high-quality material in order to solve two problems at once: utilitarian, protecting the walls of the house from external influences, and aesthetic, giving the building a decorative look. In deciding which brick is better for the foundation basement, it is necessary to give preference to red burnt brick, which is resistant to aggressive environments.

In the case of finishing the plinth of the pile-and-screw foundation with brickwork, it is necessary to install the base in the form of a strip of reinforced concrete or a metal profile. Bricklaying occurs with dressing. To connect the elements, a cement-sand mortar is used. The thickness of the seams is 10-12 mm.

Facing the basement of a private house is important, so you should carefully consider the choice of material for work. It acts not only as a decorating element, but also is a reliable protection of the entire building from the effects of atmospheric and mechanical factors.

Water destroys the building structures of the building, making them unusable, reducing the service life. This is especially true for the underground part of the house, which is exposed to several types of moisture at once. Outside, rain and melt water has a devastating effect on it, and groundwater causes trouble in the soil, the level of which may vary depending on the season. Waterproofing methods for the foundation of a building depend on its type and method of manufacture (tape, slab, pillars or piles).

How does moisture affect

There are several ways in which water can lead to the destruction of a concrete foundation:

- Washing out of the structure of particles, the formation of bumps and potholes due to aggressive components in rain or ground water.

- Destruction when water penetrates into the body of the foundation and freezes it there. The fact is that water is the only substance on the planet that, when it goes into a frozen state, expands, and does not decrease in volume. Getting into the capillaries, it exerts strong pressure on the foundation from the inside, which leads to the appearance of cracks and crevices.

That is why the waterproofing of the foundation is important and should be carried out immediately after the construction of the structure.

Types of moisture protection by location

In general, the foundation waterproofing device is divided into three groups:

- horizontal;

- vertical;

- blind area device.

Depending on the type of foundation, several methods can be applied simultaneously.

Combined moisture protection

Horizontal is designed to prevent the penetration of moisture between different levels. It can be made from various materials. It is provided for all types of foundations (tapes, slabs, pillars, piles).

The vertical one is needed in order to The groundwater could not affect the foundation. Not all types of grounds need such protection. Required only for strip and column supports at home. Horizontal protection is provided for all types (device of tape, plate or free-standing supports).

The blind area device protects the base from the penetration of rainwater and melt in the spring. Here, the width of the structure is essential. If it is insufficient, then the moisture will be removed a short distance and will be able to get to the foundation. This type of protection reduces the load on all others, allowing them to increase their service life.

Vertical and horizontal insulation

Waterproofing with roll material

Waterproofing with roll material Foundation waterproofing can be carried out using various means of protection. Separately, it is worth considering the vertical and horizontal views and the blind area, since the materials in these cases will differ quite a lot.

Protection of the buried part of the building with vertical and horizontal insulation suggests that materials can be used for the following methods:

- pasting;

- coating;

- penetrating;

- plastering;

- injection;

- mounted;

- structural (additives in concrete).

It is worth separately understanding what material to use in each case.

Okleyechnaya

Such protection of the structure is carried out using roll options on a bituminous binder. Fusion or bonded material can be used. Built-up types imply the presence of an adhesive layer that is heated when high temperatures and stick to the surface. To fix the insulation without an adhesive layer on the base, it will be necessary to use bituminous mastic as a connecting agent.

Covering materials include:

The use of roofing material is the most common method

The use of roofing material is the most common method - only(the material is outdated and it is not recommended to use it as a protection for the critical structures of the house, but it is worth noting its low cost);

- glassine(waterproofing of the foundation based on thick dense cardboard, which is impregnated with bituminous binder, cannot be attributed to reliable and durable methods, but will significantly save money);

- ruberoid(remains the leader among rolled insulation due to its affordable price, the service life is quite short);

- polymeric materials impregnated with bitumen fiberglass or polyester backing(here, as an example, the following common options for protecting the walls and foundations of a house from moisture can be given: Linokrom, Gidroizol, TechnoNIKOL, Stekloizol, Bikrost, etc.).

The last group is the most reliable option, but the price of such material can be quite high.

But here it is worth considering their long service life, which will reduce the frequency of repairs. The advantages of the pasting method include the fact that it can be provided for various surfaces:

- concrete;

- wood;

- metal;

- asphalt concrete;

- old waterproofing coating (during repair).

Coating insulation

Foundation waterproofing in this case is most often performed using bituminous mastics. To protect the buried part of the building and the walls of the house, one-component and two-component compositions are used. In addition to bitumen on the market building materials now you can find more reliable and modern options:

- polymer resins;

- bitumen-polymer resins;

- bitumen-rubber mastics.

Unlike conventional bitumen, which cracks when low temperatures, these mixtures with additional additives are resistant to cold. The disadvantage of more modern options is their price, which cannot compete with conventional bitumen-based mastic. The latter is best used to protect the structures of the house with a deep location of groundwater.

Penetrating insulation

Waterproofing the foundation in this way prevents moisture from entering the concrete capillaries. This increases the strength of the surface layer of concrete. Waterproofing a strip foundation in this way is often carried out using an additional coating or pasting layer.

On average, the penetration depth is 15-25 cm, but some materials are able to go deep by 90 cm. It is important to note that such methods are only suitable for concrete. When used on brick and stone, they are useless.

The most common compositions for this method of processing steel:

- "Penetron";

- "Peneplug";

- "Hydrohit";

- "Penecrete".

- "Osmosil".

Protection of the concrete base from moisture

Protection of the concrete base from moisture The technology for protecting the foundations and walls of the house in this way implies a thoroughly cleaned, degreased and even base, therefore it is recommended for use on new buildings.

Paint and plaster insulation

Waterproofing the foundation with your own hands using paint and plaster compositions is not durable and reliable. If possible, it is better to give preference to other ways to protect the foundations and walls of the house, since the average service life of such materials is 5 years.

Injection isolation

Technique for introducing polyurethane resin into the base

Technique for introducing polyurethane resin into the base The option is suitable for repairing a base that has already been put into operation. The technology allows you to protect the foundation without excavation work. Injectors are introduced to the supports and deliver the insulating substance. The following materials can be used as raw materials:

- foam;

- resins;

- acrylate gels;

- rubber;

- cement-containing mixtures;

- polymer compositions.

Mounted insulation

Waterproofing the foundation in this way allows you to most effectively deal with the high level of groundwater and their high pressure. It is mainly used for strip foundations when it is required to protect an underground room.

The most reliable way of mounted waterproofing can be called a steel caisson. In this case, the structure of the walls and floor of the basement is sheathed from the inside with sheets of steel 4-6 mm thick. The option is very expensive, so it is extremely rarely used.

Brick walls are sometimes erected outside, but in most cases this method is used in conjunction with a pasting or coating option. The brick is more likely not to protect the foundation from moisture, but to protect the waterproofing from mechanical damage.

blind area device

Do-it-yourself waterproofing of the foundation in this case involves using the following blind area materials to protect the structure from the outside from atmospheric moisture:

Blind area production

Blind area production - concrete;

- asphalt concrete;

- clay;

- paving slabs;

- diffusion membranes.

The choice of the method of manufacturing the blind area depends on the preferences of the future owner of the house, the architectural solution and the availability of materials. The cheapest option for the blind area will be its laying of concrete or asphalt. This option does not have an attractive appearance, but allows you to protect the foundation without much labor. In addition, savings on raw materials for manufacturing are provided. The blind area device made of concrete or asphalt is popular in the mass construction of multi-apartment residential buildings and administrative and public buildings.

Waterproofing technology depending on the type of foundation

Each type of support under a building needs certain protection options. Before waterproofing the foundation, you need to find out what is required for a full range of activities.

Strip foundation protection

The waterproofing of the strip foundation is different for the monolithic and prefabricated versions. Let's take a look at the assembly first. To prevent damage to the underground walls of the house and flooding of the basement, the following measures will be required:

- arrangement of a reinforced joint between factory-made foundation slabs and concrete blocks of basement walls;

- laying the roll material in the first seam between the blocks, which is located below the basement floor level;

- rolled material is mounted along the edge of the foundation at the junction of the walls and the supporting structure;

- vertical insulation of the underground part of the tape from the outside;

- blind area device.

Strip base protection

Strip base protection It is important to note that at the junction of foundation slabs and concrete blocks, it is impossible to lay materials on a bituminous binder. This can lead to displacement of elements relative to each other. Only a thickened concrete joint is suitable here. Insulation along the edge of the foundation is necessary so that the different moisture content of the material of the supporting parts of the structure and wall fences does not lead to destruction. For horizontal insulation, gluing methods are used.

It is better to perform vertical insulation from the outside, since this will not only protect the room, but also the load-bearing elements. In new construction, walls can be treated with gluing or coating materials. The interior is being renovated. In this case, a penetrating or injection type is used.

If you need to perform a set of waterproofing works for a monolithic tape, then it is worth considering the following measures:

- vertical isolation;

- waterproofing along the edge of the foundation;

- blind area device.

Materials are selected in the same way as for the prefabricated version.

Protection of columnar and pile foundations

A simple method of moisture protection

A simple method of moisture protection Here the simplest type of protection against moisture is used. It will only be necessary to make insulation along the edge of the foundation. Its location depends on the material of the grillage. If the strapping is made of the same material as the foundation, then the roll materials are laid at the point of contact between the grillage and the walls. You can consider another option. For example, wooden house rests on metal piles. In this case, the lower crown of the walls will serve as a grillage, so the insulating layer is laid on the heads of the supporting elements.

Foundation plate protection

To protect against moisture, the following measures will need to be provided here:

- concrete preparation of lean concrete to protect the slab from underground water and level the base;

- waterproofing for concrete preparation;

- protection from external moisture.

Foundation slab waterproofing

Foundation slab waterproofing For the manufacture of the second layer during the device of the plate, roll methods. It is best to focus on modern materials, since after pouring the slab, it is almost impossible to monitor the condition of such insulation or carry out repairs. For small buildings with a low degree of responsibility and low water saturation of the soil, polyethylene film is often used.

To protect the plate from moisture that can get from above, it must be treated with penetrating compounds. Sometimes in private housing construction they resort to using the following method: a solution for penetrating insulation is introduced into the concrete.

Also, after pouring the slab, it will be necessary to provide for the laying of roll material in the places where the walls are supported.

Before you properly waterproof the foundation (tape plates, piles, pillars), you need to carefully study the issue. It is important to use quality materials. If you save at this stage of construction, you can spend a large amount of money on repairs during operation.

Protecting the inside of the base before pouring concrete

Waterproofing the foundation is the key to it long service and reliable protection against climatic and geological factors. If the foundation does not have moisture protection, or it is too weak, then the foundation will collapse from dampness and groundwater penetrating into it, which may contain aggressive impurities, accelerating the destruction process.

Insulation also plays an important role in protecting the structure from heaving soils. The organic binder surface does not allow ice to stick to the concrete, providing only its sliding. Insulation work should be carried out immediately after the concrete structure has completely dried, in dry weather at positive temperatures.

Many protect only the upper part of the foundation or that part of it that is above the ground - this is wrong, as well as processing only the outer or inside designs. Waterproofing work should be carried out on the entire surface of the building, which will be affected by moisture.

Types of waterproofing works

Waterproofing the foundation with coating mastic before laying bricks

Measures to protect the foundation from moisture are divided into types:

- Coating waterproofing. Such protection is carried out with organic binders (bitumens, mastics and emulsions based on them with special additives) and polymer compositions. They can be applied either manually, with a roller or brush, or with a special gun using compressed air. Coating materials are very thick, before use they should be diluted with solvents or heated to liquid state, according to the manufacturer's recommendations. Such compositions are usually delivered to construction sites in buckets or barrels.

- adhesive insulation. As a rule, these are materials based on polymeric fabrics or paper, impregnated with compositions with organic binders. For ease of transportation and storage, they are produced in the form of rolls. Before application, the roll is unwound, the waterproofing is cut, after which it is applied to the concrete structure. During the production of works, in order for such material to stick to the surface, it is heated with a gas burner so that the binder on the mounting side becomes liquid, after which the material is applied and leveled with a roller or trowel, removing dents and removing excess air from under the material. Pasted insulation is more reliable and durable compared to the coating type, since it is not erased during the seasonal movement of soils, thanks to the use of a fabric frame, which makes the entire insulation a single rigid element.

- Processing with liquid glass. For such protection, a special composition is used, which includes water-soluble substances based on quartz sand. When applied, such a composition penetrates deeply into the pores of concrete, and after hardening forms a durable protective layer on which additional insulation can be applied. It is not recommended to use such compositions separately, since they dissolve when exposed to moisture.

If liquid glass is added to concrete during its preparation, then the mixture, after hardening, will better resist the effects of moisture, since the additive will slow down its penetration into the depths. However, this will reduce the strength characteristics of the concrete structure, for which it will have to be reinforced with reinforcement. This option is well suited for light structures, such as a bathhouse or a barn.

Features of work with various types foundations

Roll protection of the base of the building before laying blocks

Protective work can be performed on all types of foundations, regardless of their design and depth, even if the foundation is made in the form of masonry. All work must be carried out in accordance with the requirements of GOSTs and SNiPs in order to exclude premature destruction of the protective layer. If the surface needs to be insulated or plastered, then such work should be carried out only after the waterproofing layer has completely solidified.

In addition to the insulation of the side faces, protection against moisture from the lower part of the monolith should be provided. For these purposes, rolled insulation is used, which spreads on the drainage layer or sand bedding, before installing the formwork and pouring the mortar. Before laying, the concrete surface should also be treated with a binder.

If the project provides for pouring the grillage slab along the pile field, then only the grillage needs to be insulated, the treatment of piles with such compositions is not provided.

Block masonry

Scheme of waterproofing of block foundations of buildings

If the foundation is made of masonry blocks, then it must be isolated only with gluing material. Before applying it, the surface should be leveled with a layer of cement mortar, and only then proceed with gluing. Combining coating and pasting insulation is not recommended, since the mounting side of the roll material may not stick to the bituminous coating due to the difference in composition.

So that the insulation of the outer surface of the foundation does not wear out too quickly, it should be protected with a blind area, this will prevent excess moisture from entering the ground.

It should also be remembered that in the presence of groundwater close to the surface, waterproofing alone cannot be dispensed with, since it is not designed to protect the foundation from such an amount of moisture. To prevent flooding in this case, it will be necessary to arrange drainage systems. Only in combination with them, insulation can protect the foundation from the intense effects of large amounts of moisture.

The decision on how much the foundation should stand after pouring should be made taking into account a complex of factors. The determinants in this case are the structural construction of the base of the building, design features structures and the standing time required for the full maturation of concrete. It should be remembered that failure to comply with the period during which the foundation structure must stand before building a house can lead to partial or complete devaluation of the load-bearing properties provided for by the project.

Concrete care work

Construction rules SP 70.13330.2012, which updated the text of SNiP 3.03.01–87, prescribe to withstand concrete before stripping with the implementation of measures for its care. Data on how long the concrete laid in the formwork that forms the contours of the foundation should stand is prescribed in paragraph 5.4.1 of the Rules.

All surfaces must be reliably protected from possible evaporation of the water contained in the solution. It is also necessary to protect the freshly laid concrete mixture from atmospheric precipitation on its surface. Such measures should be carried out before construction throughout the entire period until a strength set of at least 70% of the passport is ensured.

After stripping, it is necessary to create conditions for maintaining temperature and humidity in values that optimally correspond to the increase in the strength of the concrete structure. The rules do not allow walking on the surfaces of concreted structures until the concrete gains a strength of 2.5 MPa. Accordingly, it is impossible to install overlying formwork, carry out brickwork, erect wooden walls and perform other construction or auxiliary operations.

Curing concrete

The concrete mixture dries and obtains the necessary and sufficient strength values in the process of passing through two successive interrelated stages:

- Grasping stage. Preliminary setting of the concrete solution laid in the formwork in summer at an ambient temperature of about 20 ° C occurs during the day. In cold seasonal periods it is necessary to use available means of heating and apply heat-insulating structures. It should be borne in mind that the setting processes begin to occur within the first two hours from the moment of mixing. concrete mix water. That is why the operations of mixing the mixture and laying concrete in the formwork should be as close as possible to each other in time intervals.

- Curing of concrete. Concrete strength gain occurs in the process of hydration - the formation molecular bonds particles of water with the substances that make up the mixture. Hydration takes place in a narrow range of temperature and humidity, which must be ensured by concrete care measures. The importance of careful control of the course of the physical and chemical process in the mass of a reinforced concrete structure is explained by the complete dependence of the quality of the structure.

It is natural to assume that the period during which the foundation must be defended is directly related to the strength gain of the concrete that forms its basis. Ready-mixed concrete grades M-200 and M-300, which is made on the basis of Portland cement M-400 and M-500, respectively, gains 70% of the strength required before the start of construction and standardized by SP 70.13330.2012 in 28 days at its average daily temperature of 20 ° C. A change in the average daily temperature inevitably leads to other indicators of strength. The dependence of the gained strength is clearly visible from the table:

It is natural to assume that the period during which the foundation must be defended is directly related to the strength gain of the concrete that forms its basis. Ready-mixed concrete grades M-200 and M-300, which is made on the basis of Portland cement M-400 and M-500, respectively, gains 70% of the strength required before the start of construction and standardized by SP 70.13330.2012 in 28 days at its average daily temperature of 20 ° C. A change in the average daily temperature inevitably leads to other indicators of strength. The dependence of the gained strength is clearly visible from the table:

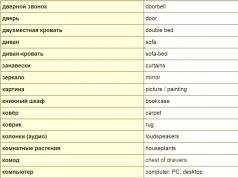

| Concrete grade | Standing time (days) | Strength of concrete (% of normalized) depending on the average daily temperature (оС) of the concrete mass | |||||

| -3 | +5 | +10 | +20 | +30 | |||

| M-200, M-300 | 1 | 3 | 5 | 9 | 12 | 23 | 35 |

| 2 | 6 | 12 | 19 | 25 | 40 | 55* | |

| 3 | 8 | 18 | 27 | 37 | 50 | 65 | |

| 5 | 12 | 28 | 38 | 50 | 65 | 80 | |

| 7 | 15 | 35 | 48 | 58 | 75 | 90 | |

| 14 | 20 | 50 | 62 | 72 | 90 | 100 | |

| 28 | 25 | 65 | 77 | 85 | 100 | - | |

The dependence of the holding time of the foundation on its type

The insinuations that the finished foundation, after gaining the normalized strength of the concrete components included in it, should stand for a year or a winter, are absolutely untenable. A common misconception about the need to withstand the structure until the end of the ongoing sedimentary-shrinkage processes arose as a result of the substitution of concepts. A fully erected building is subject to aging before the start of finishing. This is explained simply with an example. existing varieties structural structure of foundations.

Video on how to speed up the hardening of concrete

Pillar foundations

The columnar foundation is a series of separate pillars, for the arrangement of which brick or stone masonry is used, often the foundation pillars are made of concrete or reinforced concrete. To give the foundation elements additional stability, a grillage is equipped - a reinforced concrete tape that connects the headbands of the pillars.

This type of foundation is classified as a light variety, therefore, the foundation base not loaded with the weight of the building is subject to increased mobility during soil movements with heterogeneous morphology, and can be easily deformed as a result of frost heaving. The foundation of a columnar structure cannot, by definition, stand up, and the construction of walls must begin immediately after the setting of the masonry mortar or the curing of concrete.

Tape type foundations

Tape reinforced concrete foundations can be equipped in two types:

- shallow foundations are equipped for the construction of light buildings and with their soles rest on soil horizons located above the freezing level;

- deeply buried options involve the construction of bulk structures with great weight on them, the level of occurrence of their sole exceeds the depth of soil freezing.

A tape shallow foundation experiences loads that are similar in tension and strength to the effect on columnar options with a grillage. If such a foundation is allowed to stand during the period when active heaving of the soil occurs under the influence of freezing and thawing of ground moisture, the possibility of its deformation is very likely.

Foundations of a deep-lying belt type rest with their soles on dense horizons and are not affected by soil shifts. Shrinkage processes in the concrete mass are completely completed after reaching the standard strength, and the settlement of the structure under the action of its own mass, without taking into account the weight of the building, is completely leveled by expansion joints.

Plate varieties

Monolithic foundations are simply calculated and equipped; they provide a foundation for a building under construction with sufficient strength characteristics. The uniform distribution of the load on the soil base due to the large supporting surface causes minimum value specific ground pressure. Properly prepared sandy or sandy-gravel cushion under the foundation slab helps to prevent its significant sedimentary movements.

The stability of the building erected on the slab foundation directly depends on how carefully the preliminary earthworks were carried out. The amount of time how long a monolithic foundation should be defended is again determined only by the period necessary for concrete to gain strength.

Pile foundations

The foundations of buildings on piles, with any technology for their arrangement, ensure the transfer of load to deep, often primary, horizons of soils and rocks. This type of foundation construction completely eliminates the possibility of building deformation, regardless of how much time is allotted for their standing after installation is completed.

The determination of the time for how long the foundation should stand after pouring should be correlated with the time period during which ready-mixed concrete will gain the strength normalized by SP 70.13330.2012. Additional holding is not advisable, and in cases of using columnar structures and strip foundations of shallow occurrence, it is even contraindicated.

Developers often face the question of how much the foundation should stand after pouring. The strength of a reinforced concrete foundation depends not only on the quality of reinforcement and concrete. The monolith must still gain enough strength before walls can be erected on it. Let's try to figure out how much the foundation should stand before building a house.

Cured concrete is an artificial stone obtained from a mortar composed in certain proportions of cement, sand, gravel and water (composition of concrete for the foundation, proportions in buckets and kilograms). An unambiguous answer to the question: how long should the foundation stand after pouring - does not exist. Although any builder can name average figure- 28 days.

But the process of curing concrete is affected by:

- brand of cement (choice of brand of concrete for the foundation of a private house);

- the percentage of cement and water in the concrete mixture;

- weather conditions and air temperature.

The process of a set of design strength characteristics can be divided into two stages:

- grasp;

- hardening.

Foundation strength table.

grasping

The concrete mixture is in a liquid - or mobile - state for some time. This phase can be increased in time by constantly stirring the solution (how to properly pour the foundation under the house). For this reason, concrete is delivered to construction sites in concrete mixers. Although this process has a downside: if the mixture is left in the mixer for too long, its quality changes, and for the worse.

The setting period is directly dependent on the air temperature. For example, at zero temperature, the setting process begins after 6-10, and ends 15-20 hours after the mixture has been kneaded.

If it is thirty-degree heat outside, then an hour after preparation, the concrete will begin to set, and this process will be completed in 1.5-2 hours.

hardening

At this stage, in fact, there is a set of strength characteristics of concrete. If you ask a professional how long a strip foundation should stand, he will ask you a counter question: what time of the year are you going to stand it?

If it is cold (at a temperature of 0 degrees), then after 28 days it will gain only 65% strength. With minus (-3 degrees Celsius) for the same period of time, this figure will be only 25%.

If the weather is moderately warm (+20 degrees), then in four weeks the foundation will gain 98% strength. At 30 degrees, concrete will need only 14 days for this.

There is a parameter "stripping strength". It is specified in the relevant joint venture and is 70% of the brand strength.

In accordance with this, the formwork can be removed from the foundation no earlier than after:

- 7 days - at an average daily temperature of +20 degrees;

- 14 days - at +10 degrees.

Table of concrete strength depending on the hardening time.

When can you start building walls?

We figured out the concrete strength set. But how long after pouring the foundation can you start laying walls (how to calculate concrete for the foundation)? There is an opinion among private developers that reinforced concrete must stand for at least a year.

And some believe that 3-4 months is enough. There are impatient builders who start laying walls a week after pouring the foundation.

So, how long after pouring the foundation can walls be erected?

Experienced builders do the following:

- if it is planned to build a two - three-story house, the construction of enclosing structures is started 46 days after pouring the monolith. If the construction period falls in autumn or winter, it is recommended to increase the above period to 60 days. They do the same if they are not sure about the quality of concrete or the brand of cement (what brand of concrete is needed for the strip foundation);

- after the first floor is erected, work is suspended for 7-10 days. During this time, the foundation adapts to the load. If cracks occur in the monolith during a break, then this problem is easier to solve at this stage;

After the specified break, further construction of the house can be continued as usual.

If you are interested in how much the foundation for a foam block house should be, keep in mind that all of the above rules and recommendations apply to this option (what kind of foundation is needed for a foam block house).

"Shelf life" of the foundation

And how long can a foundation stand without a house? Indeed, it is often necessary to see such a picture: the monolith was prepared, and further construction was frozen. After a couple of years, the process decided to continue. But there is doubt about the safety of the structure.

If the foundation was properly preserved - covered with floor slabs, waterproofed, and groundwater drainage measures are fully implemented, there is hope that the structure has been preserved in proper condition.

If none of the above has been done, invite specialists for a technical examination of the foundation. Without checking its condition, building walls is risky.

Video about how much the foundation hardens.

How long after pouring the foundation can a house be built?

- depending on what brand the foundation is. and in principle it is possible in a couple of weeks. the mortar has a setting in 12 hours and a complete hardening in 10-18 days.

- usually the walls begin to be erected a week after the foundation is poured,

during this time, he is gaining 70% of brand strength, which is quite enough,

anyway, in the remaining three weeks you will not load it up to 100%.(and if the house is one or two floors, then never load 100% at all)

- According to SNiP, it is supposed to load (up to 70%) loads after the foundation has taken 70% strength. That is, 100% is achieved after 28 days at an ambient temperature of 25 C, respectively, the lower the temperature, the longer the setting (but not lower than +10).

Accordingly, it is better to start a partial load after 14-18 days, subject to the temperature and humidity conditions. It is necessary to water the concrete, it is better to cover it with rags or shavings, for moisture. If you load earlier, the concrete will settle around the reinforcement and the reinforcement will not interact with the concrete, as a result, the foundation and structure will crack. We need a little more information from you. - it is hard to say. it all depends on many factors. if the house is big, then it is better not to rush

- Summer residents never had enough time. forces and money to build a house in one season, therefore, nonsense about a year's "exposure" and shrinkage of the foundation was invented and firmly entered into use. There was no question of learning at least something about the soil under the house, so any experience has the right to exist, even if it contradicts generally accepted standards.

- Concrete gains full strength in 28 days BUT after a week you can already start Concrete

- How concrete will set. two hours later .. the house is not being built in five minutes .. . and everything will settle down. .But the main thing is the washing of the foundation, which especially increases the strength. Peppercorns with barbecue and mushrooms ... when the participants in the holy ritual are carried on a stretcher ... then the house will stand for a CENTURY!!

- if by the evening they poured it, then in the morning dismantle the formwork and mark the columns and so on. and until 28 days pass, the overlap of the first one and even the little things will be poured. this is nonsense for a well-reinforced foundation. 15 years of practice, although there is no winter here and the soil is very heavy clay.

- there is a clear example from acquaintances the house was built in the 60s. the foundation was poured and it stood for two winters. then the walls. the house is still standing without a single crack and evenly. and not far from them, made recently and using fast technologies (they did not wait until shrinkage occurs) and has already cracked. draw a conclusion. no need to rush)))

- Shrinkage is not needed, concrete will harden for 28 days, the house can be built, and there will be shrinkage along with the house, wait to do the finishing if the house is stone, but for example, you can immediately frame the frame. If the foundation is left for the winter, it must be mothballed. When concrete stands unloaded in the winter without conservation, this is even worse. Water enters the pores of concrete, if such a foundation stands for several years, destruction will occur.

- It depends on what kind of foundation)) it's not only about the strength gain of concrete - at least 28 days.

No matter how a comrade with Ava Einstein puts cola, everyone who goes against his dissenting opinion,

you (building on your own), asking a similar question (that is, not knowing the elementary in construction), all the more you cannot know exactly how your soils will behave and whether the foundation is correctly selected and installed.

what I’m leading to: it’s one thing if defects appear only on the foundation (during settlement), it’s another if they touch the whole house (up to the roof).

Fix the jambs on the foundation - one cost,

but saving the building as a whole is different !!! and not a fact .. what happens)) .

so personally i would prefer to survive the winter and the beginning of spring (thaw, rains.. floods), may have to think about drainage.

Here's what you need to be concerned about. before thinking about the walls - this is the correct waterproofing of the foundation so that it does not absorb moisture .. it does not transfer it to the walls and there was no damage during freezing (it is better to insulate the foundation before the walls are erected).

Be patient with half a year, read more. . find out .. all of a sudden you missed something))

- I disagree about shrinkage - complete nonsense. If there is a correct reinforcing cage, i.e. reinforced concrete, then such a foundation will not break. And before winter, it is better not to leave the foundation uncovered. Some correctly noted that it is necessary to wait 28 days, but 21 days are quite enough.

- usually after the foundation has shrunk, that is, it has fallen into place. let's just say after the winter you have to look

- Shrinkage is definitely needed, so after winter.

- Cherns 28 days

- Standard concrete gains strength after 28 days, but even when building high-rise buildings with the help of professional formwork, they wait a couple of days to fill the next floor. It all depends on the air temperature, the composition of the concrete, the brand of cement and the material of the house itself.

Concreting of the tape and slab foundation of the house is carried out according to a long-established technology. At first glance, there is nothing complicated in the work, but during pouring, during the process and after the monolith has cured, many questions arise related to various nuances. Some of them are so important that their non-compliance may well lead to one or another destruction of the structure. For example, how much time should elapse after pouring before formwork is removed and how long should concrete be cured before the next stage of work begins? Among experts you can hear different opinions, but the rules, nevertheless, exist.

What threatens the untimely removal of formwork

As you know, a mushy concrete mortar is used to fill the strip or slab foundation of the house. After laying it in the formwork, the processes of cement hydration and gradual hardening of concrete begin. For their correct completion, it is necessary to allocate a certain amount of time required for the foundation to stand and gain design strength.

If the formwork is removed from the structure immediately after the cement has set, then there will be a possibility of the monolith spreading into different sides. A fragile “body” will not only be unable to take on loads, but also retain its own shape. This is especially true for massive foundations.

If the formwork is removed from the strip foundation after the cement mortar has set, but before it has gained a certain strength, then cracks will appear in the structure. For the underground part of the house, which takes over and distributes all the loads to the ground, this threatens to split and completely destroy already during the operation of the house.

How long should the foundation stand after pouring? There is no single answer to this question. The average period of time is determined by 28 days, but in some cases 15-20 days are enough. In difficult conditions, the deadlines need to be extended.

Professionals assure that the foundation of the house must stand for at least a month before loading it.

To prevent the building from shrinking, warping and collapsing, it is necessary to strictly observe the implementation of building rules and the technology for erecting the underground part of the house. The foundation is the support of the building, therefore it does not tolerate negligence, inability and lack of basic knowledge.

How long should the foundation stand

The time periods specified in the standards, provided for the concrete structure to stand, do not always correspond to real time. They are influenced by external factors such as:

- ambient temperature;

- humidity regime;

- the presence of precipitation;

- season;

- ground conditions;

- terrain;

- dimensions and type of foundation - tape, slab, columnar;

- design strength of concrete;

- quality of materials;

- the presence of groundwater in the area;

- construction technology;

- the presence of additives;

- the value of the calculated loads.

In addition to the above points, situations may arise that affect the period during which the foundation of the house will have to be defended before further work begins. In some cases, the concrete structure is left even for the winter, so that when the soil thaws, it is easier to identify defects and correct shrinkage. At the same time, the monolith is securely covered. It is noteworthy that not a single standard can take into account all the nuances, so the question of how much the foundation of the house will be defended is decided on an individual basis.

When determining the timing, the worst conditions for the site should be taken into account. The stock, in this case, will play a positive role.

How is the foundation of the house laid?

The first time the concrete structure is allowed to stand immediately after pouring. This period lasts up to seven days, during which the surface is watered. The concrete sets and begins to harden. From above, the foundation is covered with plastic wrap, but you can also use:

- waterproof fabric;

- sawdust;

- straw.

Polyethylene is lifted before watering, and other materials are moistened from above. They perfectly retain moisture, preventing water from evaporating ahead of time. The duration of solidification of the monolith depends on the season. After about a week, and in the hot season - after 10-14 days, watering is stopped, but the cover layer is left up to 28-30 days after the concrete mixture has been placed into the formwork. Thus, primary maturation occurs, which is quite sufficient for foundations installed on a base buried below the level of soil freezing.

But in practice there is also a secondary standing. It concerns situations when shallow foundations have to be erected on heaving soils. In this case, the hardened concrete structure is left to winter. With the advent of spring, the movements are recorded, and the base is strengthened by adding sand or gravel with the obligatory layer-by-layer tamping.

Experts assure that it will be better if the foundation stands without load for a whole year. It turns out that in the first month after pouring, concrete gains strength up to 70-75 percent, and the remaining 25-30 percent in the next 11 months. From this we can conclude that if the construction time allows, then preference should be given to a longer time period. If the period of construction of the building is limited by rigid frames, then the installation of the walls of the house is started 28 days after the pouring of the foundation. Under favorable climatic conditions and the use of light materials in the enclosing structures, the period can be reduced to two weeks.

On what day after pouring concrete can waterproofing be applied. Is it worth doing waterproofing for the winter, but not covering it with earth?

it all depends on the temperature ... it is believed that concrete gains strength after 28 days ... the main thing is that the surface is dry ... just look at the color - the concrete has brightened, touch it - you don’t feel the damp surface - you can make waterproofing ... it will not stick to the damp surface ...

30 days it is desirable to stand, and so you need to look at its humidity

Definitely not, the complete drying of concrete takes about a month, especially at this time.

Good afternoon. It is necessary to build on what kind of waterproofing (bituminous mastic, welded roll, sprayed rubber-bitumen, sprayed polymers, cement-based THIXOTROPIC PLASTER, polymer membrane), based on this, the application time is from a couple of hours after formwork removal to several weeks. backfilling is not necessary, some types of insulation will need to be protected before backfilling.

Instruction

Wetting the foundation can lead to its complete destruction. The degree of danger depends on the hydrogeological conditions of the region in which the building was built: the level of groundwater, soil density, freezing depth, and others. The main factor that destroys the concrete base of the building is the hydrodynamic expansion of moisture accumulated in the foundation during freezing. Erosion can bring no less problems to homeowners, because high humidity is always accompanied by the appearance of microorganisms that slowly but surely destroy the very structure of concrete from the inside. With a low soil density, the accumulation of moisture in the foundation area can lead to uneven shrinkage of the soil, due to which the foundation will receive additional load and may simply burst. Based on the foregoing, it can be unequivocally stated that an individual approach should be provided in all cases to protect the foundation from moisture.

The main method of protecting reinforced concrete foundations from oversaturation with moisture is waterproofing. By its type, it can be moisture-proof, used at a foundation depth of less than one meter, and pressure water-resistant, which is used for structures laid to a considerable depth. According to the principle of application, waterproofing materials also come in different types. Tape or roll insulation is a wide tape of water-repellent material that is attached to the outer surface of the foundation. Coating insulation is a hydrophobic paste or mastic that is applied to the surface of a concrete structure. Penetrating waterproofing closes the pores in concrete and forms a thin film on the surface, which together prevents the penetration and accumulation of moisture. The use of such materials solves the problem of wetting the foundation in most cases.

At high level groundwater and heavy rainfall, you need to think about the design of the drainage system. It is an intricate network of pipes through which excess moisture is removed from the house and discharged into the soil or into a specially prepared well. Protecting the foundation from water by this method shows very good results in practice, but is often associated with serious material costs. Equip the drainage system only in exceptional cases and, as a rule, after complex geological studies.

The source of moisture in the foundation area is not only groundwater, but also precipitation. To avoid leakage of rain or melt water under the foundation, it is required to build a blind area around the entire perimeter of the building. This is a cement or concrete screed, from 60 centimeters to several meters wide, forming a monolithic structure with the foundation. The main function of the blind area is to protect the foundation and the soil around it from moisture seepage, dropping it onto the soil at a safe distance. Often, only this measure is enough to keep the foundation dry throughout the year.

Isolation of the building from moisture is a very important part in any construction work, after which the building will be firmly, reliably and efficiently insulated from rain moisture and ice, and, of course, groundwater. Even more waterproofing is needed if you plan to build a room where water can easily get in. The better the waterproofing, the more durable the house will be. With good waterproofing, you will never see small insects, fungus and mold on the wall, especially in rooms that are below ground level.

Do-it-yourself waterproofing of the foundation is a procedure that is absolutely realistic to do without outside help, but we must not forget that this is a responsible job and should not be approached carelessly. You must have certain skills and abilities, and you also need to have information about all the nuances of the territory, and, of course, you need to follow safety precautions.

We will describe and explain six different options.

- Plinth processing

- Foundation slab processing

- Monolith processing

- Balcony processing

General rules for construction work

Now there are various options for strengthening the foundation:

- Okleyechnaya- pasted over with rolled material, which is treated with an adhesive composition. It can be self-adhesive, heat-on, or weldable.

- Impregnation- treated with a composition that penetrates well into the soil. It fills the capillaries in the material and creates a layer of several tens of centimeters.

- Coating- treatment with a composition that has a high resistance to moisture. For example, polymers or bituminous mastic.

- mounted- it is carried out using geomembranes with spikes made of polymers, which are assembled into a washing, moisture-proof surface.

According to these technologies, it is necessary to protect not only the foundation, but also the adjacent structures:

- Ground floor

- Basement floor and walls

- Foundation in foundation

The waterproofing layer in any building must be solid and not damaged. Preferably completely flat. Sometimes another waterproofing layer is installed from the back of the structure, which takes the brunt. This is done if there is a danger of flooding with groundwater. To avoid this problem, the building is protected with a blind area. Surface water is everywhere, so this part is installed everywhere. There are no exceptions in this case.

There is another problem. It's called groundwater. They are not always located on the same level with the foundation on the plots. The question is where they are and how deep. If they are higher than the foundation, then in addition to waterproofing, drainage work must also be carried out. This procedure is necessary so that the water is as far away from the building as possible. It also lowers the groundwater level and thereby lowers the pressure on the base of the building. Without drainage, this cannot be achieved. Regardless of the above, one must also take into account chemical composition water. In some areas, one has to deal with harmful groundwater. This water is harmful to. Based on this, all materials must withstand aggressive environments.

Plinth processing

The outer side of the basement is certainly protected. Sometimes even to the level of the first floor. This is done because frost sometimes remains on the blind area. Based on this, in addition to all the work, the plinth needs to be lined with frost-resistant and moisture-resistant finishing materials. Do not forget! If you use high-quality products, follow the technology, don't be lazy - this will be the key to the longevity of your home!

The basement continues the foundation of the wall. The basement is the top of the foundation, it is above ground level, about 2m. But in some cases, a floor can be quite high off the ground and create another floor that is half underground and half inside.

Given that the plinth continues the foundation, more time should be devoted to insulating them. You must not allow the outside to get wet and the capillary moisture to pass down. We must not forget that from various factors moisture can rise to the second floor. Moisture evaporates from the wall, so dampness can be on two floors. Therefore, make reliable isolation!

There is another option for finishing the base - vertical insulation. The point of this isolation is that the whole system works as a whole. For this, liquid waterproofing is most often used. With the help of molten rubber, you can get a water-repellent coating from a monolith without seams. This material is very easy to apply, works great in tandem with other materials. Therefore, it can be used for both brick and concrete (monolithic or block)

Foundation slab processing

To install it, you need to dig a pit. After the measures taken, the block is laid on well-trodden sand and gravel. The thickness of this embankment is approximately 35 cm, the thickness of the block is from 25 to 45 cm. This foundation can be from a monolith or prefabricated. If you have a monolith, then the formwork is poured with concrete with a pre-installed reinforcement frame. In another case, the base is made of prefabricated reinforced concrete structures, for example, road slabs. With any installation option, you must know that the ground water must be removed without fail!