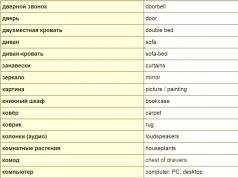

Polymer-sand products are products made using waste polymers ( plastic bags and PET bottles).

Is it profitable to engage in this production and how quickly will it pay off?

The main forms of polymer-sand products are facing and paving slabs, curbstones, tiles and occasionally manholes.

Polymer-sand products have a number of useful properties:

high impact resistance (compared to cement-sand products) - they do not break during installation and during transportation;

durability - their service life exceeds 100 years;

lightness - polymer-sand products are two times lighter than cement-sand analogues;

cheapness;

not spreading flame and electricity;

impact resistance external environment- they withstand temperature fluctuations from -60 to +200 degrees, are resistant to ultraviolet radiation, absorb sound well, and this is their advantage over metal roofs. Polymer-sand tile does not absorb moisture, washes well, does not accumulate snow, and retains its original color for up to 30 years.

In Europe, these are ANDERA polymer-sand tiles, which have received recognition at various exhibitions and the approval of the Swedish Consumer Association (SVK).

The production technology of polymer-sand materials is very simple. They are made up of polymer sand and dye. The ratio for tiles is 24/75/1, for paving slabs - 5/94/1.

For work, you will need soft (bags, plastic wrap) and hard (polystyrene, polypropylene, PET bottles) polymers. Their ratio is 50/50. Do not use rubber and refractory polymers - polycarbonate, fluoroplastic.

Raw materials for business can be found in a regular landfill or recycling centers. You can buy sorted and cleaned waste, but it will cost much more, and there is no great need for this, because paper and food waste burn out and will not have any effect on product quality.

1 ton of untreated waste on average in Russia - 3 thousand rubles.

As a filler for finished products sand is used. The moisture content of the sand should not exceed 10%, and the clay content should not exceed 20%. Permissible fraction - up to 3 mm.

1 ton of sifted dry sand costs an average of 300 rubles in Russia.

The third component is Bayerferrox dye (Bayer). Its average cost is 90 rubles/kg. If you work without dye, then the finished product will have a gray color (curb stone, paving slabs).

Main steps technological process:

Crushing of polymeric waste. We use the device - polymer crusher PT 2003.00.000 (capacity 900 kg/h).

The resulting mass is placed in an extrusion machine (Extrusion machine PT 2004.00.000 with a capacity of 85 kg / h), where the polymers are heated and mixed. The finished mass cools down and the slightly hardened conglomerate is again placed in a crusher to obtain an already fine homogeneous fraction up to 10 mm.

The resulting polymer mass, prepared sand and dye are mixed and poured into a melting and heating unit (APN PT 2002.00.000 with a capacity of 250 kg / hour). This stage is the most important, mixing, heating the mass and enveloping each particle of sand with a polymer takes place here. This is achieved by a peculiar design of the shaft, the blades of which move the mass with different speed in three heating zones, and this leads to high-quality mixing of the mass.

The resulting mass of the consistency of a tight dumpling dough is placed in a molding press, where the mass is put into molds, and under pressure (250 tons) it is cooled. To obtain paving slabs, the mass is cooled evenly. To get tiles, to give it shine Bottom part form cools faster than the top.

The average performance of this production line is 100 sq. m per day (two working shifts of 8 hours).

For production, you will need a room with an area of 150 square meters. m s supply ventilation. Ceiling height - 4 m. Renting such a room will cost you an average of 15 thousand rubles per month.

Since the products and equipment are original and non-standard, certificates and licenses for production are not required.

Calculations for 100 m2 of products:

polymer 520 kg x 3 r / kg = 1560 rubles

sand 1580 kg x 0.3 r / kg = 474 rubles

dye 12.5 kg x 100 r / kg = 1250 rubles

electricity 25 kW x 16 hours x 1.8 r / kWh = 720 rubles

salary - 8 people for 8000 rubles. = 64000 rubles per month: 30 = 2133 rubles

water supply - 100 rubles per day

room rental - 15000: 30 = 500 rubles per day

transportation costs - 300 rubles per day (calculated individually).

The total cost of 100 m2 of finished products will be 7037 rubles.

The cost of finished products for different manufacturers is 250-400 rubles per 1 sq. m. To prove yourself and enter the market, you need to take the lower price - 250 rubles per 1 sq.m. Therefore, 100 sq.m. we will sell for 25 thousand rubles. Net income minus cost - 17963 rubles. per day.

average cost production line of polymer-sand materials (for different manufacturers) - 900,000 rubles + 100,000 for transportation.

Therefore, the payback of the line with an average workload and work in two shifts is 1,000,000:17963 = 55 working days (3 calendar months).

However, by purchasing a set of drawings for the production of equipment, the payback period can be significantly reduced. For example, we purchase a complete set of drawings with all modifications of units for the production of the entire line here: www.polimercherepisa.narod.ru

Next, place an order for the manufacture of all equipment according to the purchased drawings at any tool company or machine-building plant in your city. The production time of the entire line depends on the capacity of the plant and, as a rule, does not exceed 2 months, and at the same time, its production will cost us no more than 200 thousand rubles.

Let's calculate the payback: (200,000 + 20,000 for the drawings): 17963 = 12.2 work. day.

That is, the payback period when choosing this method of obtaining equipment will decrease by almost five times.

Thus, it is extremely profitable to produce polymer-sand materials and starting a business is quite simple. In addition, the production of polymer-sand products is effective solution plastic waste problems.

Good luck in building your business!

Based on the article by Serik Ainurov for the project www.polimercherepisa.narod.ru

- 1. SAVING:

The price of our paving slabs is low for the benefits that you get by deciding to buy it. Polymer sand tiles are cheaper than good ceramic tiles, which break, cheaper than rubber and WPC (wood-polymer composite) tiles, which do not have sufficient hardness, and not much more expensive than concrete (cement-sand) with all its shortcomings;

- 2. INCREASED PRODUCT DURABILITY:

The increased durability of Tetto polymer sand tiles is due to a whole range of special technological measures during its production and the UNIQUE COMPOSITION of the polymer composite. At the stage of product release, specially selected and prepared modified polymers and components, special additives and minerals are introduced into its composition, which give the tile additional PROTECTION AGAINST THE ENTIRE SOLAR RADIATION SPECTRUM, additional frost resistance, resistance to aggressive environments and temperature changes, which in turn order increases the durability of the product COMPARED TO COMPETITIVE PRODUCTS.

- 3. INCREASED PRODUCT IMPACT:

The material itself has high strength, as a result of which it is characterized by a COMPLETE ABSENCE OF FIGHT during loading and unloading operations, especially those performed by hand, transportation, falling from a height, processing with a cutting tool.

- 4. ADDITIONAL UV PROTECTION OF THE TILE:

Tetto polymer sand tiles DO NOT LOSE COLOR under the action of sunlight and do not require additional painting, like competitors' products. HIGH UV RESISTANCE is achieved due to the high percentage of sand in the composite, the choice of special coloring pigments, additives, minerals and modified polymers, which significantly Slows down the aging process of tiles from the sun.

- 5. ADDITIONAL PROTECTION OF THE TILES FROM INFRARED RADIATION:

Most manufacturers of polymer sand tiles DO NOT USE additional protection composite from infrared radiation and at best limited to UV protection. Our company introduces special components into the composition of tiles that PROTECT PRODUCTS from the effects of this negative factor and INCREASES DURABILITY BY AN ORDER.

- 6. IMPROVED FROST RESISTANCE OF THE TILE:

The entire structure of the material is MICRO-REINFORCED, which gives the tile additional frost resistance, as well as increases the overall strength and durability of the product. Our tiles are perfectly ADAPTED to DIFFERENT CLIMATE CONDITIONS. Reinforcement of the polymer-sand composite gives resistance to frost and temperature extremes. Our company is the FIRST IN RUSSIA TO APPLY and still uses the technology of reinforcing polymer-sand products.

- 7. INCREASED RESISTANCE TO AGGRESSIVE ENVIRONMENTS:

The unique composition of Tetto tiles provides excellent RESISTANCE TO ALL KNOWN NATURAL EVENT such as acid rain, bacterial activity and lower plants, to heat and frost, hail and hurricanes, to radiation of the ultraviolet and infrared parts of the solar spectrum. The low water absorption of the material adds to its durability and does not allow it to “grow” to its surface and the structure of ice in winter, and ice easily breaks off from the surface when it is cleaned;

- 8. EASY INSTALLATION:

One of the main advantages of Tetto tiles is the COMFORTABILITY of WORK with it, it is easily processed with cutting tools, without cracking and DOES NOT BREAK during work. The installation of polymer sand tiles is SO SIMPLE that, if desired, it can be carried out even by a non-specialist. The material of the tile is viscous, which allows you to screw something to it with a self-tapping screw.

- 9. LOW WEIGHT:

The light weight of products in comparison with other types of coatings allows you to take away MORE tiles at a time and significantly SAVE on freight transportation. And on exploited roofs, the weight of the tile is of no small importance.

- 10. AESTHETIC:

We offer a WIDE color scheme tiles. Polymer-sand tiles look very AESTHETIC and will give odds to many floor coverings in terms of beauty, variety of textures, shapes, colors.

- 11. ECO-FRIENDLY:

The water we drink from plastic bottles, and which is fed into the crane by plastic pipes completely normal and harmless. Thus, the safety and environmental friendliness of polymer-sand tiles is confirmed by the LONG-TERM USE OF PLASTIC PRODUCTS IN HOUSEHOLD. The material is environmentally friendly, does not emit cement dust, which is formed during operation concrete slabs, does not emit carcinogenic substances, unlike asphalt in the heat.

- 12. UNIFORMITY:

All elements of Tetto polymer sand tiles are HOMOGENEOUS IN COMPOSITION and thus such a factor as a different coefficient of expansion is excluded, the coating FUNCTIONS AS A SINGLE STRUCTURE.

- 13. LOW THERMAL CONDUCTIVITY AND INJURY HAZARD:

It has low thermal conductivity and high heat capacity, which gives it HEAT-INSULATING PROPERTIES, which is important, for example, for stables, cowsheds, enclosures. When using it as a covering for playgrounds, INJURIES AND INCIDENCE ARE DECREASED, since the tile is warm and has plasticity.

- 14. COLORS:

Tetto sand-polymer tiles are available in a WIDE VERSION OF COLOURS, which are sure to add REFINERY to any architectural solution. The palette of colors that you prefer to see will not be lost over time, since the material is dyed throughout the entire thickness of the product.

Recently appeared on Russian market, polymer sand paving slabs, immediately won the trust and love of customers. Due to its characteristics, it has become a worthy replacement for cement tiles. Polymer tiles, the production of which takes place with the help of modern ways, easily competes with classic concrete products.

The following characteristics are considered the advantages of this material:

- strength;

- ease;

- variety of forms;

- wide scope;

- durability.

The demand for this material is constantly growing, so the production of polymer tiles with your own hands will soon become a "gold mine" for businessmen. The main thing is the right approach and a sober assessment of all the advantages and possible risks in this business.

The advantages of polymer tiles

Polymer sand tiles consist of the following components:

- quartz sand (3/4 of the composition);

- polyethylene high pressure(25% of composition);

- a small part of other refined products.

This composition makes the material plastic and resistant to negative external influences.

The advantages of the product include

- durability - polymer coating lasts up to 30 years;

- stability - the material is not afraid of frost, moisture, heavy loads, liquids containing acids and oils;

- decorative - tiles are often made in any shape. However, it often has a glossy, matte or structured surface. And also in the manufacture of polymer tiles, craftsmen can use a wide range of colors;

- no toxic fumes when exposed to direct sunlight;

- repeated use and easy repair in case of damage;

- ease of cleaning the coating (the tile is easy to clean);

- wide scope. Polymer sand tiles are used as a decorative coating for a private courtyard, parking lots, playgrounds and sidewalks in public places.

Material production

The raw materials for the manufacture of polymer tiles are simple and affordable components:

- various pigments;

- polymers;

- quartz sand.

To reduce the cost of purchasing components, you should use secondary raw materials, which will be cheaper, but will not spoil the quality of the products.

The exact recipe for making sand tiles as such simply does not exist. Each manufacturer independently develops the composition. The best option is to make a prescription for own experience, but also the masters recommend resorting to the help of a technologist.

The production technology of tiles is quite simple. It is not necessary to comply special knowledge and skills.

Since the polymer that is part of the tile has a neutral chemical composition, then only Nitric acid at certain conditions. To form a homogeneous mixture with sand, the polymer must be melted at a temperature of 180 degrees and atmospheric pressure. This process is called extrusion.

For coloring tiles different colors I use different inorganic substances: iron oxide for brown, red or orange, chromium oxide for green, titanium dioxide for white.

Do-it-yourself production of polymer sand tiles is carried out as follows:

- crushing or agglomeration of raw materials. But if you buy polymer chips, then this stage is easy to avoid;

- mixing components with a concrete mixer;

- melting of the mixed mass in APN (extruder);

- pressing products into molds;

- transportation and storage of finished products.

Necessary equipment

For the production of polymer sand tiles at home, you will need to purchase special equipment:

- crushing device;

- scales;

- concrete mixer;

- press;

- Press forms;

- cooling system for finished products;

- loader for moving finished products.

The total cost of equipment and its adjustment depends on the power and configuration of the machines. With a minimum configuration, the amount will be 800 thousand rubles.

Polymer-sand paving slabs

Work space

The room for the production of sand tiles must be at least 100 square meters. Of these, 30 will be occupied by a zone for storing raw materials and 70 - a zone for installing equipment.

It is also necessary to provide a place for storing finished products. It is often recommended to store this material outdoors.

Work force

Even for the production of tiles with their own hands, the master will need work force. Best Option will start continuous production (in two shifts). To do this, you will have to hire one master, two APN operators and one auxiliary worker in the batch. The master will spend about one hundred thousand rubles on wages for one month.

Electricity and heating

On average, the production of 1 square meter of tiles will take about 8 rubles to pay for electricity. But it will help save on heating. During the operation of the APN, a large heat transfer occurs, which replaces the heating pipes.

Sales market

The high performance characteristics of sand tiles significantly expand the scope of its application, thanks to this, sand tiles confidently replace materials such as concrete tiles, asphalt, concrete, natural and artificial stone.

The demand for tiles is constantly growing. And what is more profitable than buying materials from the manufacturer itself?

Establishing sales of your own products will be quite simple.

But for this, it is necessary to monitor existing buyers of these products.

It can be:

- various building materials stores;

- tiling companies;

- owners of private houses, summer cottages, Cafe;

- owners of restaurants, hundred, warehouses, public buildings;

- landscape designers.

It's best to decide on your target audience even at the stage of production planning, in order to please their customers and distinguish themselves favorably from competitors.

Marketing

The success of any production, even the most modern and high-quality, depends entirely on the number of customers.

And the production of polymer sand tiles attracts more and more businessmen, which increases competition in this area.

To stay afloat and get high profits, you need to radically differ from competitors. The main advantages are:

- high quality products. The sole purpose of the manufacturer must be to satisfy all the needs of its buyer. Everyone should have an individual approach;

- execution of obligations. This means that you need to respect the client. Do not let him down by breaking the agreed deadlines, do not raise prices for products without warning him in advance;

- good publicity. Nothing needs to be explained here. Everyone knows that advertising is the main driver of sales. Be sure to participate in exhibitions, create product samples, collect a portfolio of photographs of completed work.

Profitability and payback of production

The production of polymer tiles in practice pays for itself very quickly. It will take about one and a half million rubles to launch the production line. This includes:

- expenses for equipment, raw materials;

- rent;

- preparation of the premises;

- company registration.

Even the smallest tile workshop can easily produce a thousand square meters of tiles per month. One square meter on the market costs from 250 to 500 rubles. That is, on average, with a full-fledged sales of products, the profit will be 500 thousand rubles.

Business brings a decent income

This is a fairly high rate of return in a small business.

To calculate revenue, you need to subtract the following indicators:

- taxes and wages;

- rental of premises;

- utilities;

- purchase of new raw materials;

- fare.

If all costs are taken into account, then, subject to full sales, monthly profit will be equal to 60 thousand rubles. Production of polymer sand tiles - profitable business. The main thing is the observance of technology, the production of high-quality material and the active promotion of business in the market. For the active manufacture of polymer sand tiles, you will need initial capital, a small tile shop, workers and accounting. Handmade tiles always have a high price.

With a modern approach to the manufacture of polymer tiles, production will be profitable from the first month.

Video: Polymer sand tiles

Polymer sand tiles appeared on the domestic construction market recently. Such an innovation caused some distrust among buyers, but gradually polymer slabs proved their superiority over traditional pressed and cast concrete tiles.

Consider the main characteristics of polymer sand tiles, the technology of its manufacture, the scope and procedure for paving slabs on different types grounds.

Technology for the production of polymer sand tiles

When developing polymer-sand tiles, the technologists set themselves the task of creating a durable and frost-resistant material with a long service life. I must say that they succeeded and the performance characteristics of polymer sand tiles surpassed cement paving stones in many respects.

Park area paved with polymer sand tiles: photo

The working mixture for the manufacture of tiles consists of three main components:

- sand of medium fraction (no more than 3 mm);

- crushed primary polymers (secondary polymers can also be used - from an economic point of view, this is more profitable);

- dyes are inorganic pigments.

The main filler of the tile is sand, it makes up 75% of the total volume. Before use, it is thoroughly washed and sieved. After that, the sand is placed in a special oven and pierced at high temperature.

The entire production cycle of polymer sand tiles can be divided into the following stages:

- Crushing or agglomeration of raw materials. If polymer chips are used, then this step can be omitted.

- Mixing sand, polyethylene chips, dyes and additives.

- Melting of raw materials in an extruder at a temperature of 250°C.

- Pressing polymer-sand mass and forming ready-made plates.

- Product packaging.

For the manufacture of plates used modern automated equipment. The product at the output is dense and homogeneous, there are no internal and external cracks or voids throughout the entire array of material.

Technical characteristics of polymer sand paving slabs

Specifications tiles depend on the quality of the raw materials used, the structure of the working mixture and production equipment. However, one can distinguish General characteristics polymer sand paving slabs:

Advantages and disadvantages of polymer sand tiles

The combination of a polymer component with a sand filler causes a number of advantages of laying and operating paving slabs:

The disadvantages include the feature polymer products- under influence high temperatures material tends to expand. If the paving technology is not observed (the gap between the plates is less than 5 mm), then the coating may deform in the hot season - some elements will begin to warp and protrude.

Scope of polymer sand tiles

Polymer sand tiles are in demand among professional builders, summer residents, owners of suburban areas and private houses.

Paving slabs based on polymers and sand are used in the arrangement of:

Polymer sand tiles can be produced in the form of tiles for roofing. In addition, there is a facing tile made of polymers for finishing the facades of the building.

Overview of manufacturers of polymer sand products

On the market, a range of polymer sand products is presented large quantity domestic and foreign companies. Among Russian manufacturers of polymer-sand tiles, Namus LLC, Prompolimer LLC, SibTopProm-14 CJSC, Budprom-Technology Private Enterprise and Polimerika LLC have won a good reputation.

OOO "Namus"- a major manufacturer of polymer-sand products. All products of the company are tested in accordance with GOST 3634-99 before being delivered to the market. The main production is located in Tatarstan, and there are branches and sales offices in different cities Russia.

The polymer-sand tiles of Namus LLC are produced in the size of 330 * 330 mm, 35 and 20 mm thick, basic colors: green, light gray, chocolate and red. The texture of the tile can be of three types: "parquet", "smooth" and "8 bricks". The cost of paving polymer-sand tiles is about 500 rubles / m2.

In addition to tiles, Namus LLC produces from a polymer-sand mixture: curbs, gutters, well rings, speed bumps, pedestrian crossings, drainage trays, cable protection plates, monuments and storm water inlets.

Company group "Prompolymer", founded in 2006, manufactures products for various market segments: polymer sand products, building metal structures and soft packaging.

The tiles are produced in sizes 330*330 mm, 20 and 40 mm thick. Forms of paving slabs: smooth, broken stone and rhombus. The price of a tile is from 350 rubles / m2. The quality of polymer-sand products "Prompolimer" is confirmed by the sanitary and epidemiological conclusion.

Company ZAO SibTopProm-14(Tyumen) appeared on the market of polymer-sand products recently - in 2012, but already competes with experienced manufacturers.

Paving slabs are available in four basic colors: red, brown, gray and green. Plate dimensions 330*330 mm, thickness - 20, 30 and 35 mm. Paving slabs are produced in three grades - depending on the quality of the feedstock. The cost of tiles of the first grade is 490-620 rubles / m2, the second grade - 430-510 rubles / m2.

LLC "Polymerika" (Yaroslavl region) specializes in the production of polymer-sand tiles and paving slabs. The company's products have been tested for UV radiation, checked for compliance with sanitary and epidemiological standards and radiation safety indicators. Each research is confirmed by the corresponding document.

Paving slabs are produced in the size of 330*330 mm, thickness - 25, 30, 35 and 40 mm. Types of textures: smooth, parquet, curly and paving stones. The price of tiles is 495-630 rubles / m2 (the cost depends on the thickness of the plates).

Tips for choosing high-quality polymer paving slabs

When choosing a polymer-sand tile, you need to pay attention to the following parameters:

Foreign inclusions on the plates indicate the use of poorly processed or low-quality raw materials, white stains are the result of non-compliance temperature regime. The quality of such polymer-sand tiles deteriorates significantly, the strength and durability of the material decreases.

Do-it-yourself polymer sand tile laying

Paving of polymer-sand tiles can be carried out on a sand cushion, crushed stone or on a concrete screed. The choice of base for installation depends on the type of soil and the purpose of the paved area.

Laying on sand is used in the arrangement of garden and footpaths, sidewalks. If there is heaving soil on the site or the site will be used for parking cars, then the slabs must be laid out on crushed stone. Installation on a concrete screed is carried out when the tile will be used to receive heavy vehicles.

Preparatory activities

To work, you will need the following tools:

- crowbar, shovel and jackhammer - to remove the old coating and excavation;

- trowel, bucket;

- rubber mallet;

- cord and wooden stakes for marking the site and controlling evenness;

- building level;

- rake;

- concrete mixer - if the tile is laid on a concrete screed;

- mop and broom - for filling sand into the gaps between the plates.

The initial preparation of the soil does not depend on the further method of laying the tiles:

Further actions will depend on the type of flooring - sand, gravel or concrete.

Sand paving technology

Work sequence:

The procedure for laying tiles on gravel

After the “bed” for the site is prepared and the curbs are set, the following work is performed:

- Pour a layer of crushed stone 10-20 cm onto the leveled surface and level it, adhering to the selected slope.

- Tamp the rubble with a rammer.

- Pour a dry cement-sand mixture over the rubble (layer thickness - 5-10 cm).

- Level and compact the surface.

- If significant loads are planned on the paved area, then it is advisable to lay a reinforced mesh before installing the tiles.

- Lay the tiles, keeping the gaps - about 5 mm.

- Level the surface with a rubber mallet. Slopes to control the building level.

- Fill the joints with a dry cement-sand mixture (ratio 1:5) and moisten.

Gravel paving technology produces a durable surface that can support the weight of a car

Installation of slabs on a concrete base

First stage this method similar to those described above: the soil layer is removed, the surface is leveled and curbs are installed. Next, perform the following steps:

- Pour a layer of gravel or crushed stone over the entire area (thickness - 20 cm), tamp.

- Make a screed of concrete, taking into account the slope of the surface. Screed thickness - 5-10 cm.

- Paving slabs are laid on a cement mortar grade M-150 (the proportion of cement and sand is 1: 3). Instead of this solution, you can use tile adhesive - this method is more reliable. tile adhesive in this case it is recommended to combine with cement mortar in a ratio of 5:1.

- Until the solution has completely dried, the platform cannot be loaded and used.

- After the "setting" of the solution, sprinkle the surface of the site with sand and fill the seams between the plates.

- Moisten the site and wipe the seams with a cement-sand mixture.

Every year there are new and new technologies that improve the properties of familiar materials. Polymer-sand tiles are the product of such innovations. The product is universal in use, practical, durable and competitive from a financial point of view.

Polymer-sand tiles have appeared on the Russian construction market quite recently, but have already managed to establish themselves as a worthy replacement for the usual cement tiles. Polymer sand tiles today are becoming more and more popular among those businessmen who are not afraid to use innovations. Success in this business is guaranteed to you, because at present there is practically no manufacturing enterprises involved in the manufacture this product. So, you have every chance to become the first in your city.

How did polymer sand tiles appear? Initially, the developers had a desire to find a coating that would immediately solve two main problems inherent in cement tiles: low frost resistance and a short service life. It is worth recognizing that they managed to create such a product. Polymer sand tiles have many advantages:

- Durability. According to manufacturers, the service life of such material is 30 years.

- Resistance to negative influence external environment. Polymer sand tiles are resistant to moisture, frost, sunlight, oils, acids. In addition, it is not subject to point splitting.

- Attractiveness. Such material can have any shape and any surface: glossy, matte structural. Tiles can be made in any color. And most importantly - over time, it does not lose its decorative properties.

- Ease of repair.

- Ease of maintenance.

Where are polymer sand tiles used?

- In landscape design

- In the arrangement of adjacent territories

- At gas stations

- At the service station

- On the courtyards of cafes, shopping pavilions

- In parks

- For plinth cladding

- For covering flat roofs

Obviously, such products are in demand among buyers, and simple manufacturing technology and relatively low costs for starting a business allow everyone who wants to start such activities.

Who are the buyers?

Polyper-sand tiles can be implemented among:

- Direct consumers of this product: individuals, construction companies and brigades.

- Wholesale bases and warehouses.

- In retail trade: supermarkets, markets, hardware stores.

Tiling is an art

Tiling is an art Production process of polymer sand tiles

The raw materials for production are:

- Sand with a fraction not higher than 3 mm

- Primary or secondary polymers. The latter are more profitable from an economic point of view.

- Pigments organic and mineral.

The main stages of production:

- Agglomeration or crushing of raw materials. You can exclude this stage if you immediately purchase polymer chips.

- Mixing in a concrete mixer of raw materials.

- Melting raw materials in the extruder.

- Creation of forms with the help of a press.

- Shipment of products to the warehouse.

Calculation of economic efficiency

For financial plan The following parameters were taken: tiles are produced in two shifts of 12 hours each. 5.83 m2 of finished products are produced per hour, 140 m2 per day.

Finished product parameters:

- Dimensions - 330 x 330 x 35 mm;

- 9 tiles fit in 1 m2

- The weight of each item is 4 kg

- The weight of 1 m2 is 36 kg

The cost of starting production and purchasing equipment:

- Commissioning activities - 50,000 rubles

- Melting and heating machine - 540,000 rubles

- Press D2430 (100 tons) - 470,000 rubles

- Concrete mixer SBR-500 A - 69,000 rubles

- Mold "Paving slabs" - 210,000 rubles

A mold for creating a tile pattern

A mold for creating a tile pattern - Scales MK-15.2-AB20 - 4,200 rubles

Total: 1,343,200 rubles.

Including payment for rent of premises, installation of equipment, wages of labor and other expenses, the profitability of the business will be 127%, subject to the production of tiles in two shifts.

This business idea will be useful primarily to those entrepreneurs who have a construction or engineering education, but everyone can learn technology from scratch.

The main thing is the desire and confidence in victory!

If you have something to add to this article, leave your comments. We value any of your opinions!